Disassembly report: UGREEN 10000mAh magnetic wireless charging power bank PB561

Preface

Lulian has launched a magnetic wireless power bank for iPhone. This power bank has a built-in 10,000mAh capacity battery and supports 15W wireless charging and 20W two-way fast charging. It can be used for optional wired and wireless charging, which is all-round. The power bank also supports wireless charging during charging and can be used as a wireless charging pad. It has 19 built-in strong magnets and is firmly adsorbed.

This magnetic wireless power bank also supports low-current charging mode and supports charging of Bluetooth headsets and other devices, and its compatibility is very comprehensive. Its shell is made of non-slip silicone material, which has a better skin-friendly feel. Below, Charging Head Network will bring you the disassembly of the Greenlink 10000mAh magnetic wireless charging mobile power supply to take a look at the internal design and materials.

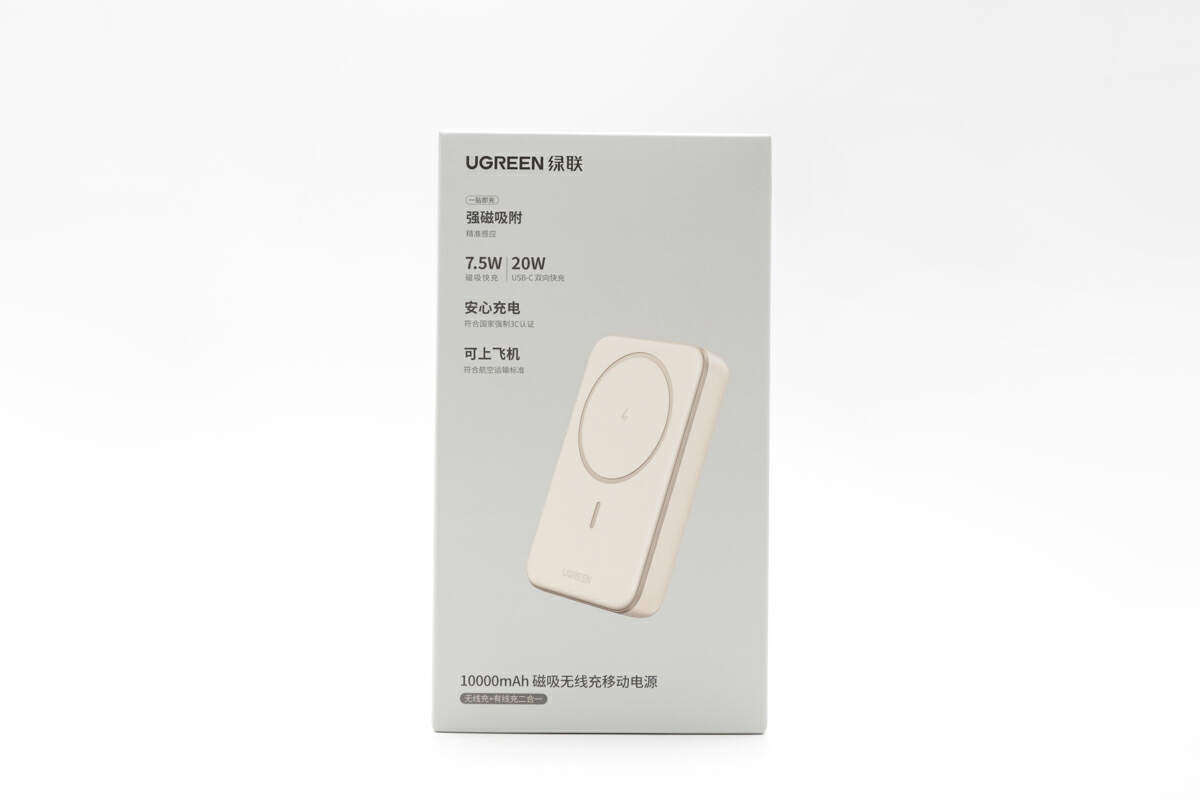

Greenlink 10000mAh magnetic wireless charging power bank unboxing

The UGREEN brand, product appearance, name, and selling points are printed on the front of the box , including strong magnetic adsorption, 7.5W wireless and 20W wired, safe charging, and aircraft safety.

Information such as product parameters and safety warnings are printed on the back.

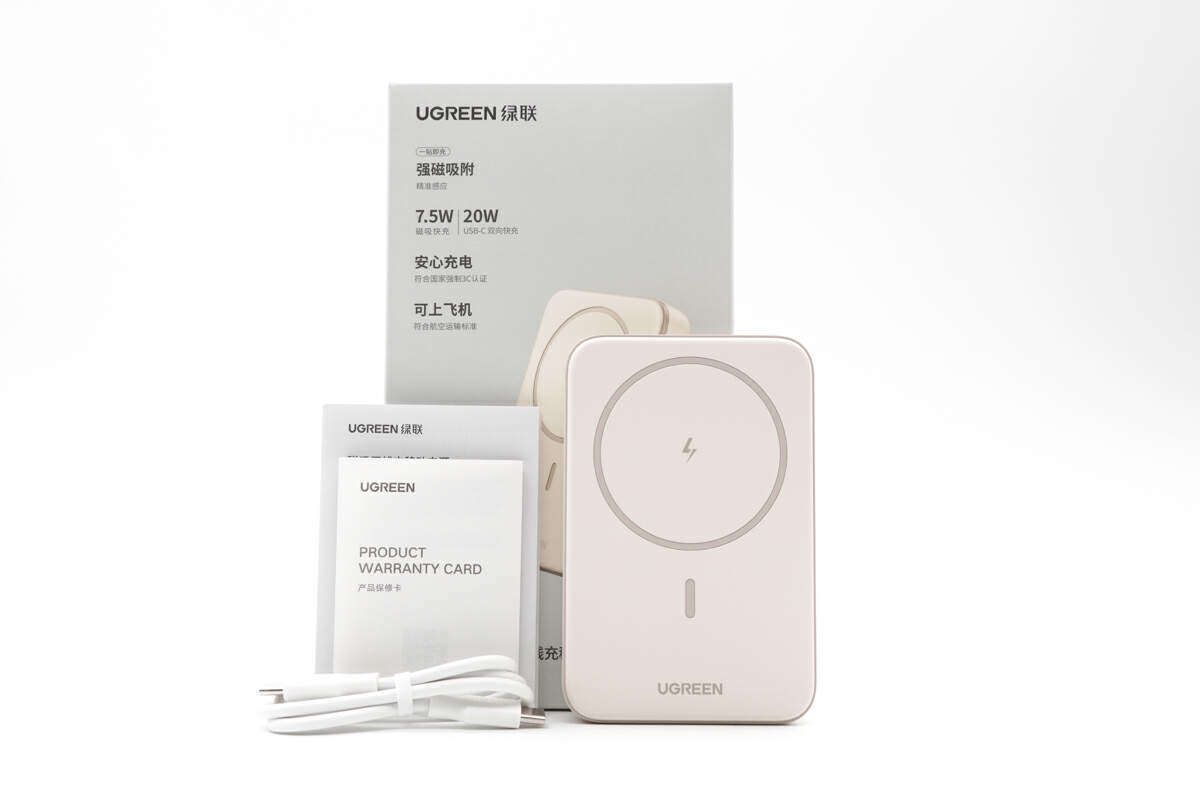

The package contains a mobile power supply, data cable, user manual and product warranty card.

The included data cable is a USB-C to USB-C short cable, which is easy to carry and use while charging your mobile phone.

The measured length of the data cable is approximately 53cm.

The data cable measured using ChargerLAB POWER-Z KM003C does not have an E-Marker chip.

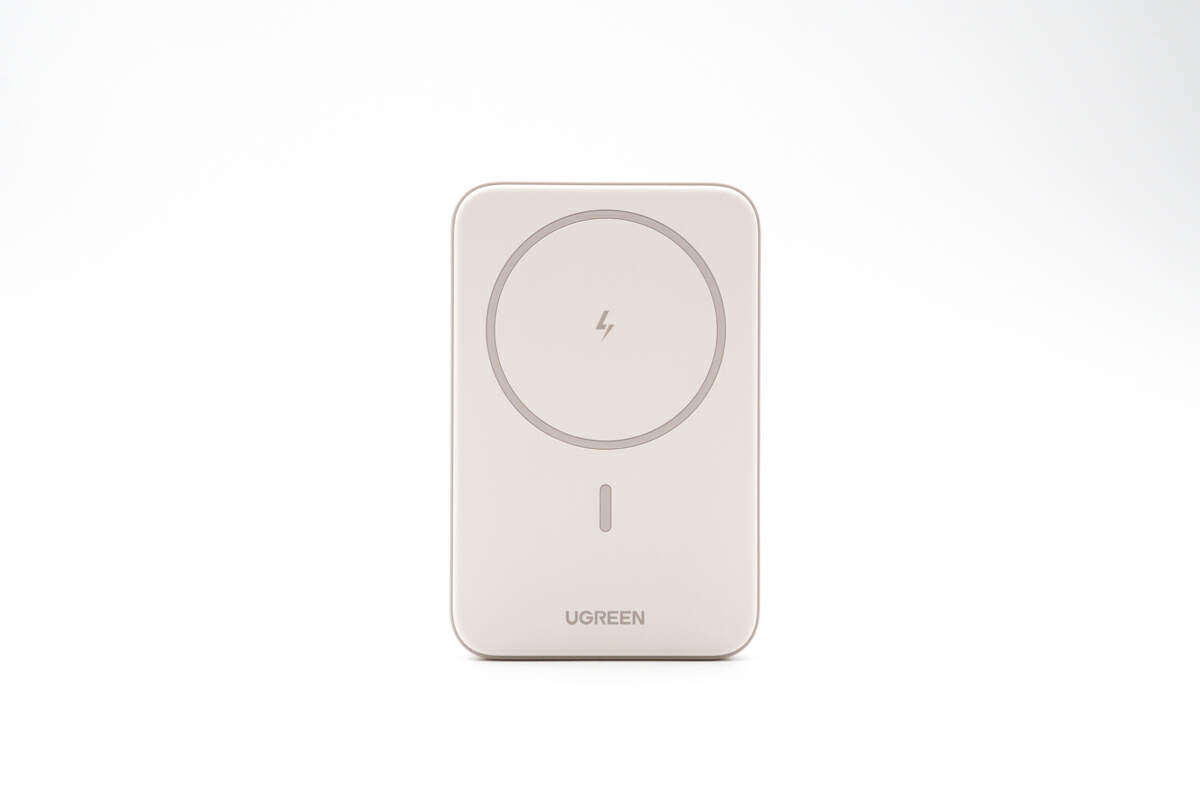

This magnetic wireless charging power bank from Lulian uses an off-white plastic casing. The edges of the body are rounded and will not irritate your hand when held. At the same time, the front surface is made of skin-friendly material with a better feel, which can ensure a better fit for the phone and long-term use . It won’t scratch the back cover of your phone either.

The edge color of the fuselage is deepened and the contrasting design makes the product more recognizable.

The front of the fuselage has a magnetic wireless charging area reminder design, and a lightning logo is printed in the center of the area.

The UGREEN brand is printed on the lower front.

The UGREEN brand is also printed on the back of the fuselage. At the same time, detailed product specifications are also printed below.

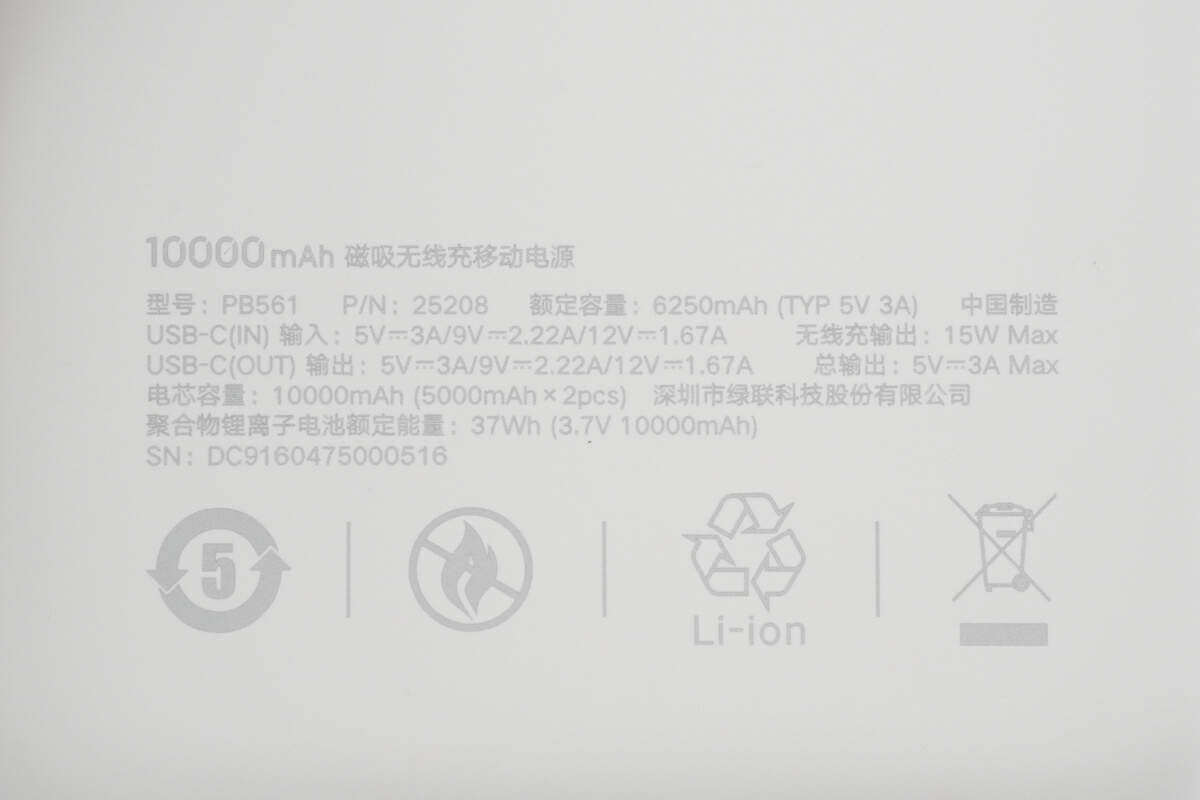

Close-up of mobile power supply parameters

Model: PB561

Battery type: polymer lithium-ion battery

Battery capacity: 10000mAh (5000mAh x 2pcs)

Rated capacity: 6250mAh (TYP 5V3A)

Rated energy: 37Wh (3.7V 10000mAh )

USB-C input/output: 5V3A, 9V2.22A, 12V1.67A

Wireless charging output: 15W Max

Total output: 5V3A Max

Manufacturer: Shenzhen Lulian Technology Co., Ltd.

The bottom of the fuselage is equipped with a fast charging indicator light, a battery indicator light, a USB-C two-way fast charging port and a power button.

The measured length of this mobile power bank from Greenlink is 105.21mm.

Width is 68.6mm.

Thickness is 19.22mm.

You can intuitively feel the size of the product in your hand.

In practical applications, it is used for magnetic wireless charging of Apple iPhone series mobile phones. The size is just right and will not block the rear camera module of the phone. Users can take photos and other activities while magnetically charging wirelessly.

In addition, the net weight of the mobile power supply was measured to be approximately 225g.

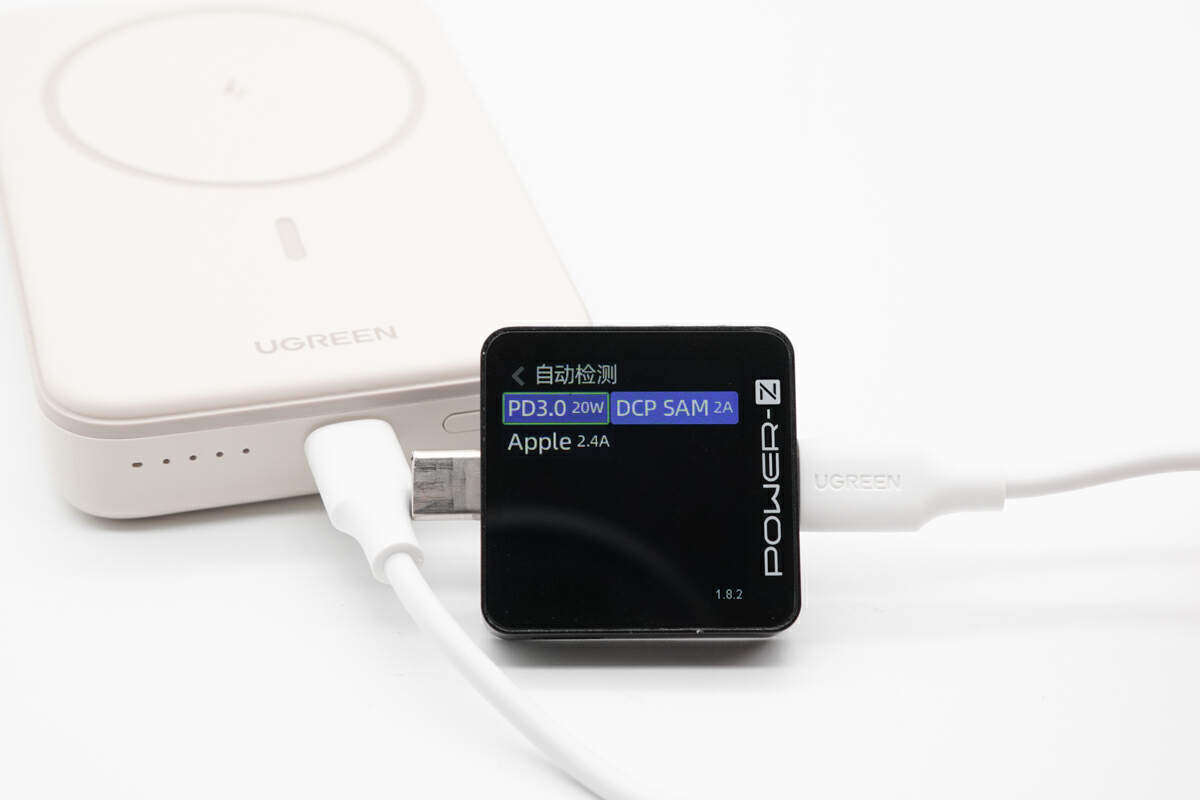

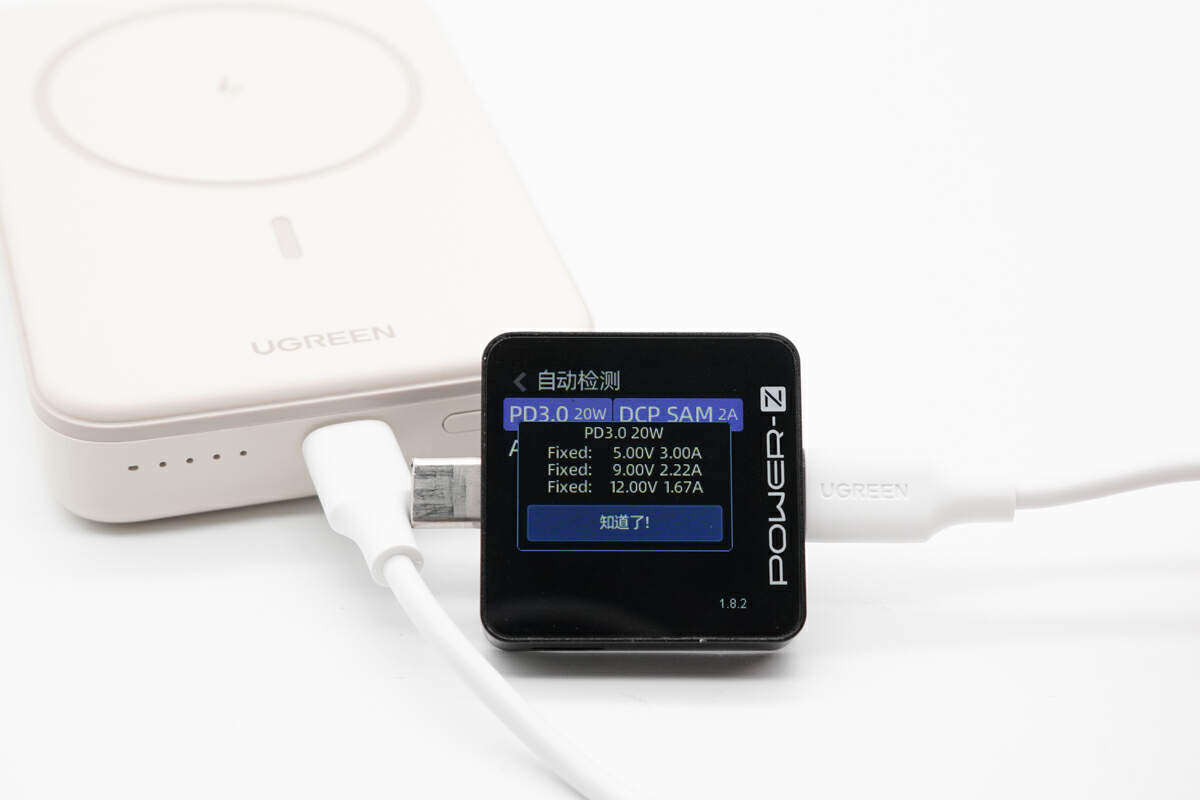

Using ChargerLAB POWER-Z KM003C, it was measured that the USB-C port supports PD3.0, DCP, SAM 2A, and Apple 2.4A charging protocols.

The PDO message shows that the USB-C port also has three fixed voltage levels: 5V3A, 9V2.22A, and 12V1.67A.

For wired charging of Apple iPhone, the measured charging power is 9.17V 2.17A 19.88W.

Greenlink 10000mAh magnetic wireless charging power bank disassembly

After reading the unboxing and testing of the Lulian Magnetic Wireless Charging Power Bank, let’s dismantle it and take a look at the internal design and materials.

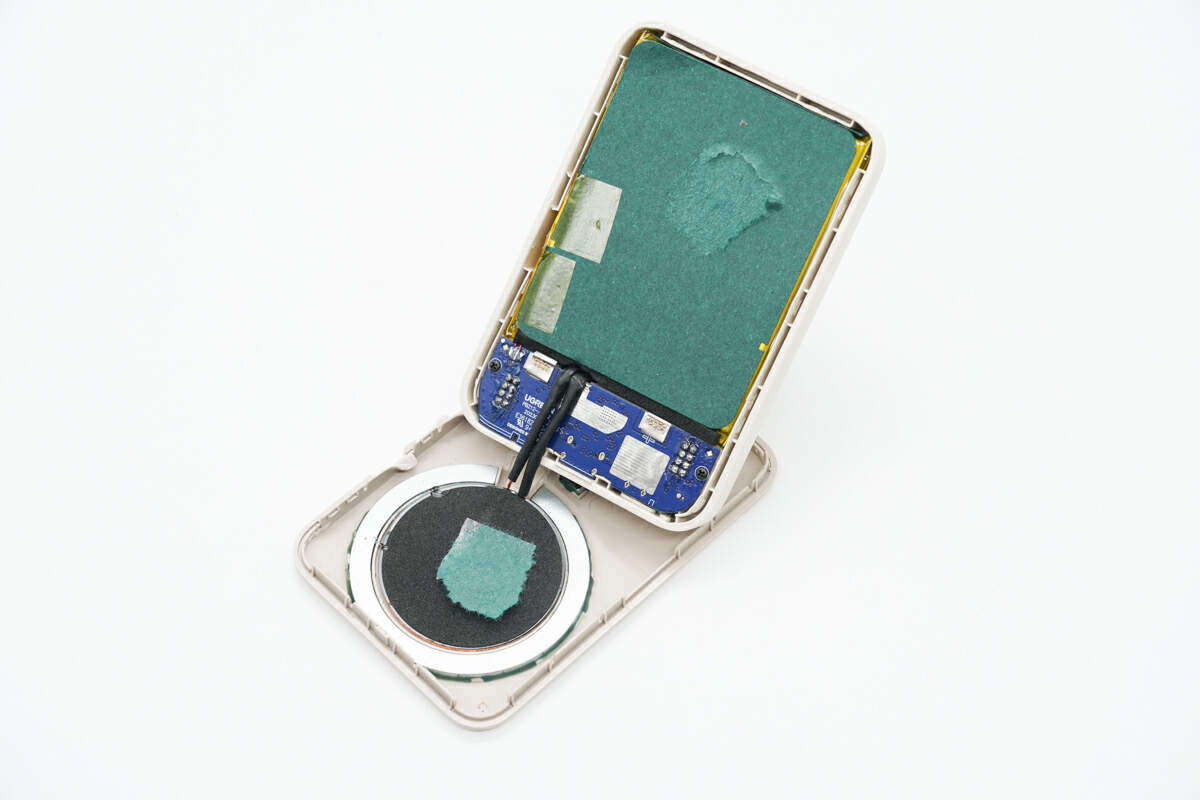

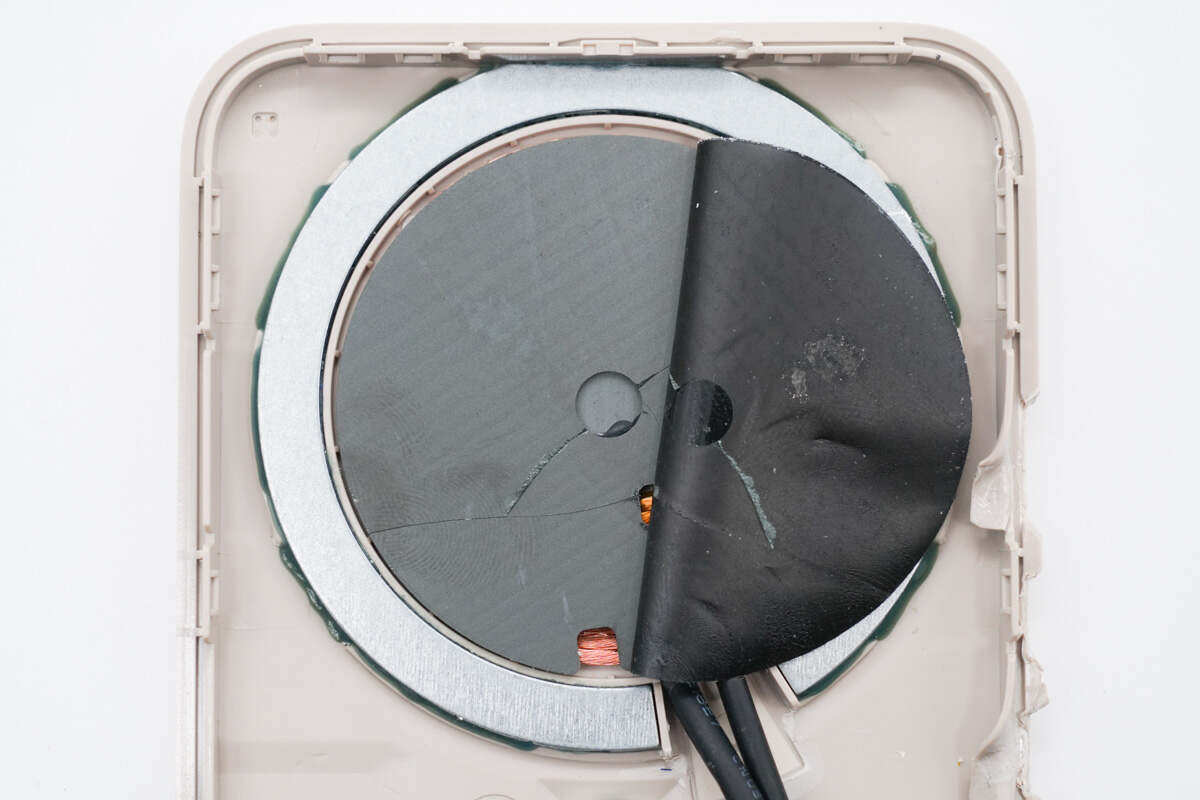

Pry open the mobile power supply shell along the seams of the shell, and stick the wireless charging coil and magnet on the cover.

The wireless charging coil enameled wire is coated with heat shrink tubing to enhance insulation.

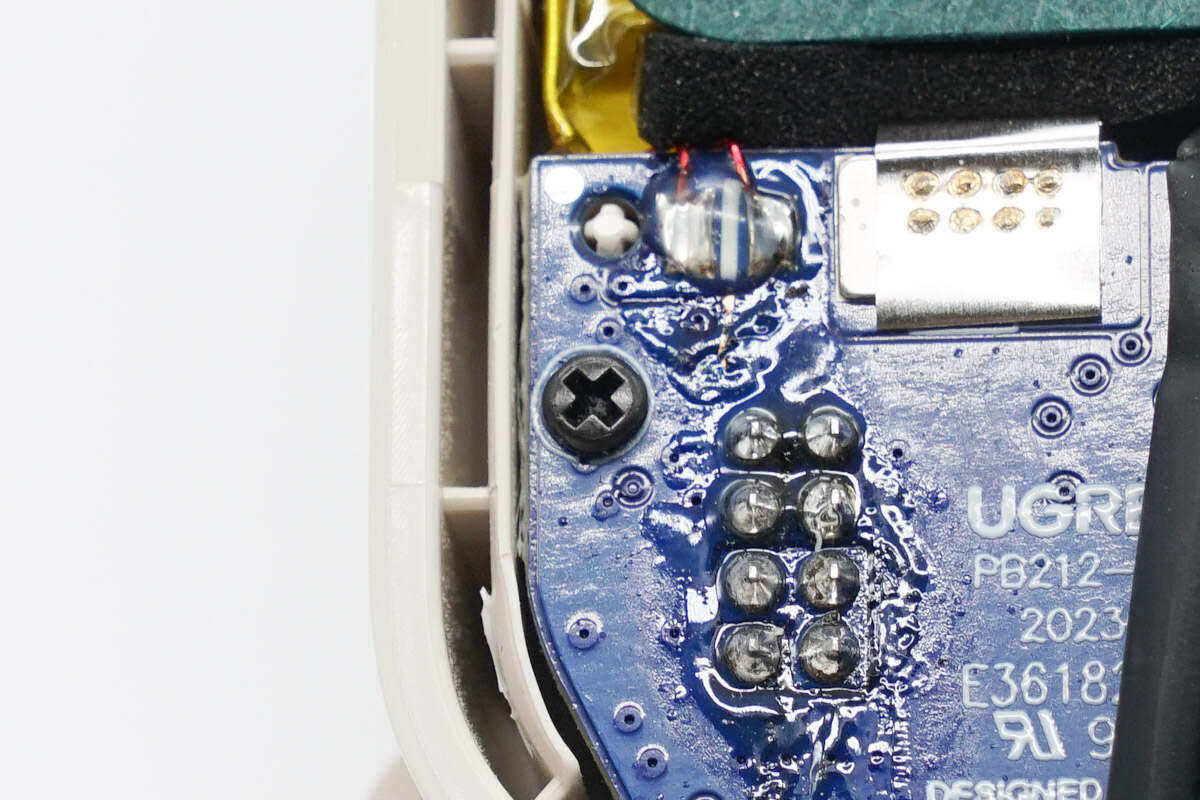

The PCBA module is fixed with screws.

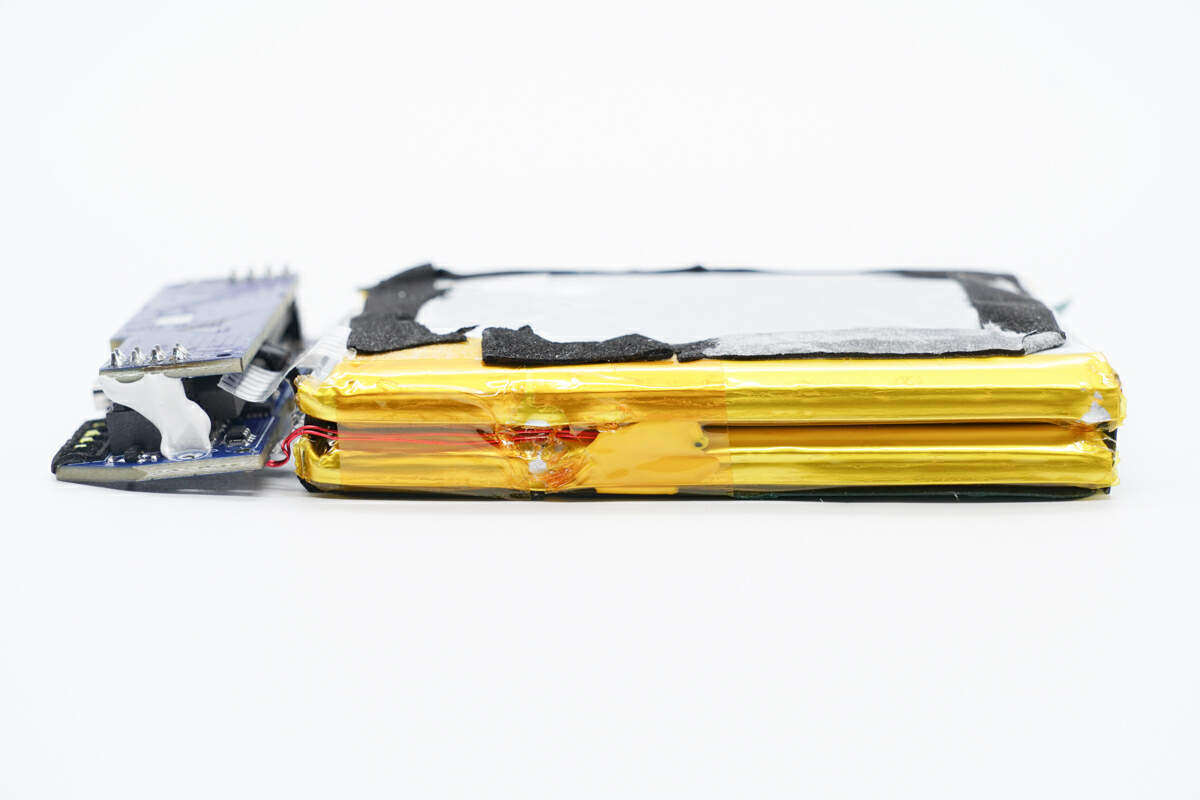

Unscrew the fixing screws and take out the battery pack and PCBA module.

Paste graphite thermal paste inside the shell at the position corresponding to the PCBA module.

Cut the connection between the wireless charging coil and the PCBA module and continue the disassembly.

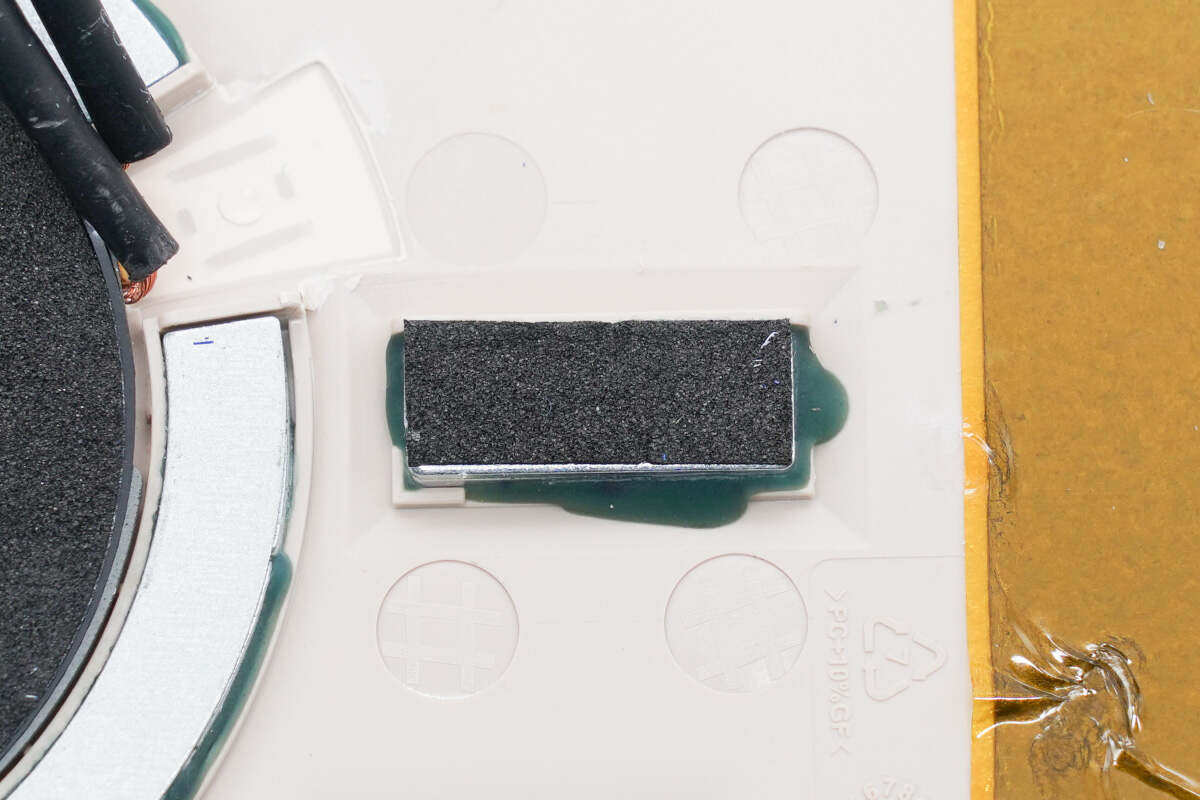

The wireless charging coil, positioning magnet and graphite thermal paste are pasted inside the cover.

Inside the panel, stick the graphite thermal paste at the position corresponding to the PCBA module.

The positioning magnet is fixed with glue.

Paste foam tape on the back of the wireless charging coil.

Peel off the foam tape to expose the magnetic isolation sheet inside.

Close-up of positioning magnet and wireless charging coil.

The magnets are glued to the inside of the case.

The wireless charging coil is wound with Litz wire.

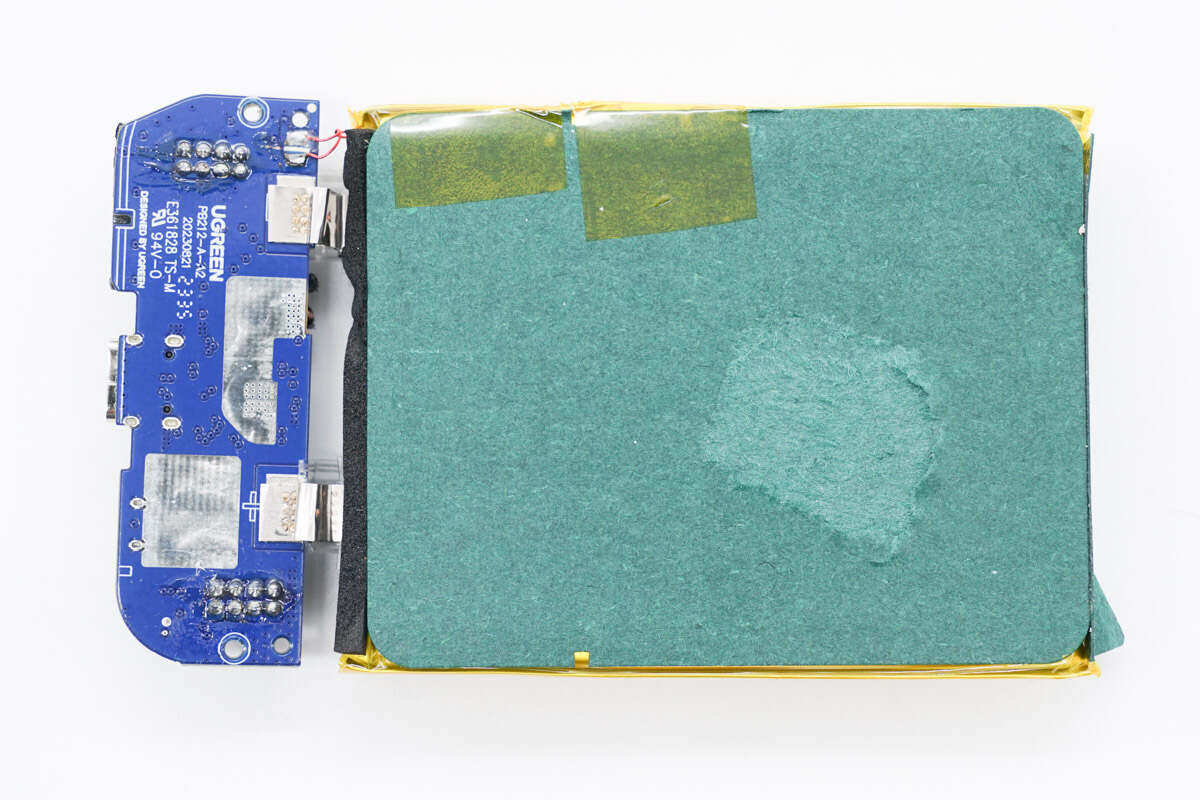

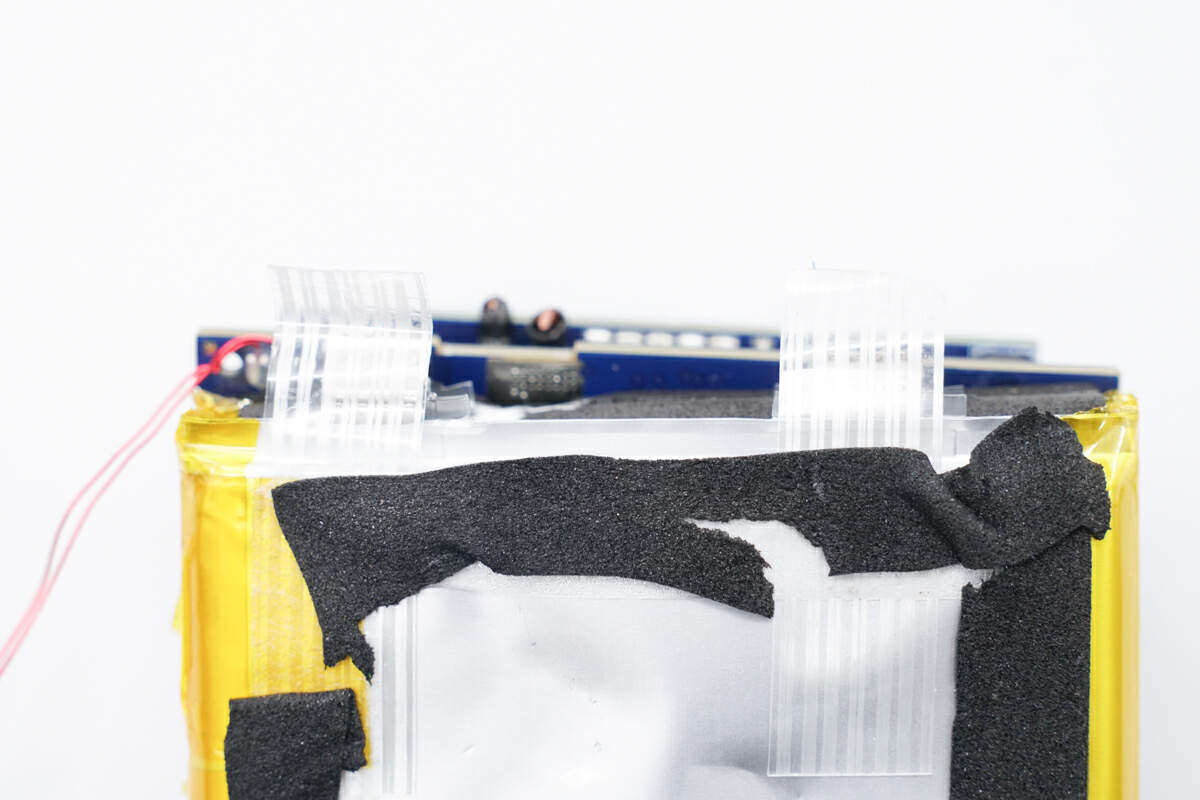

The battery pack is pasted inside the casing with double-sided tape.

The other side of the battery is pasted with highland barley paper to protect the insulation.

The bottom of the battery is pasted with highland barley paper for insulation protection.

The mobile power supply has two built-in batteries connected in parallel.

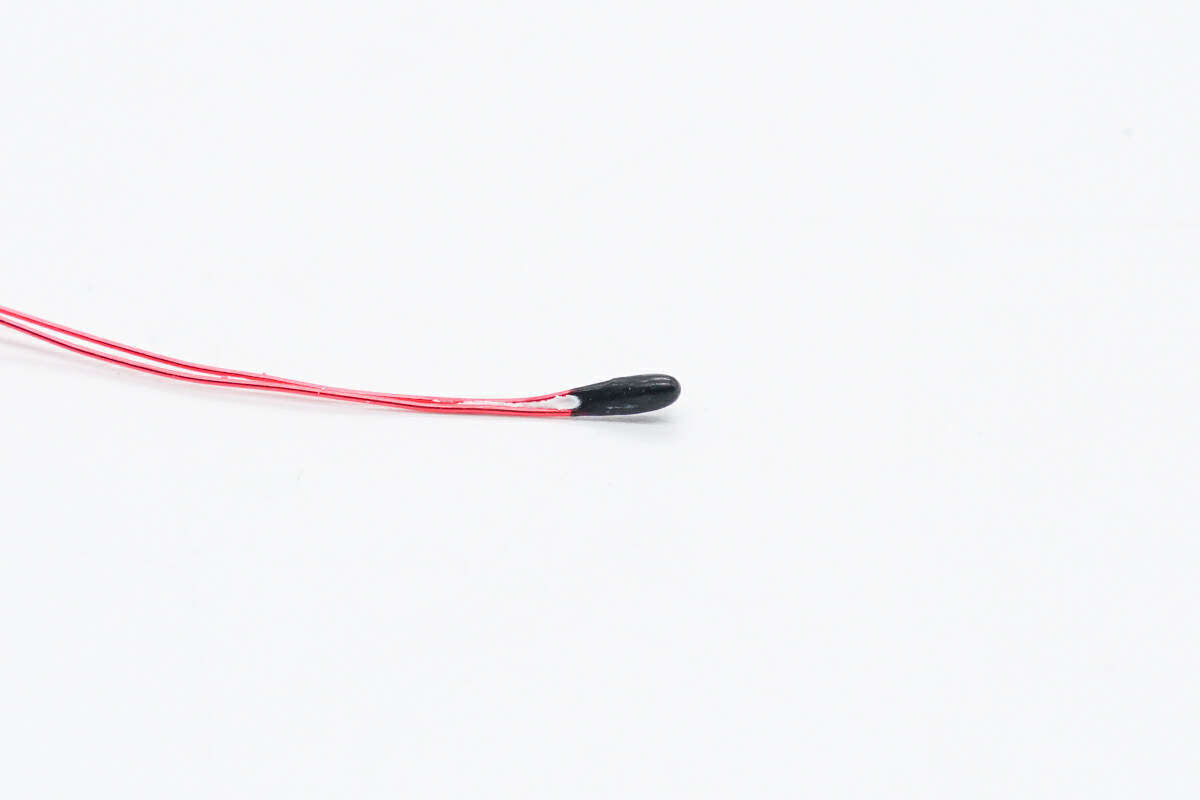

A thermistor is pasted between the two batteries for temperature detection.

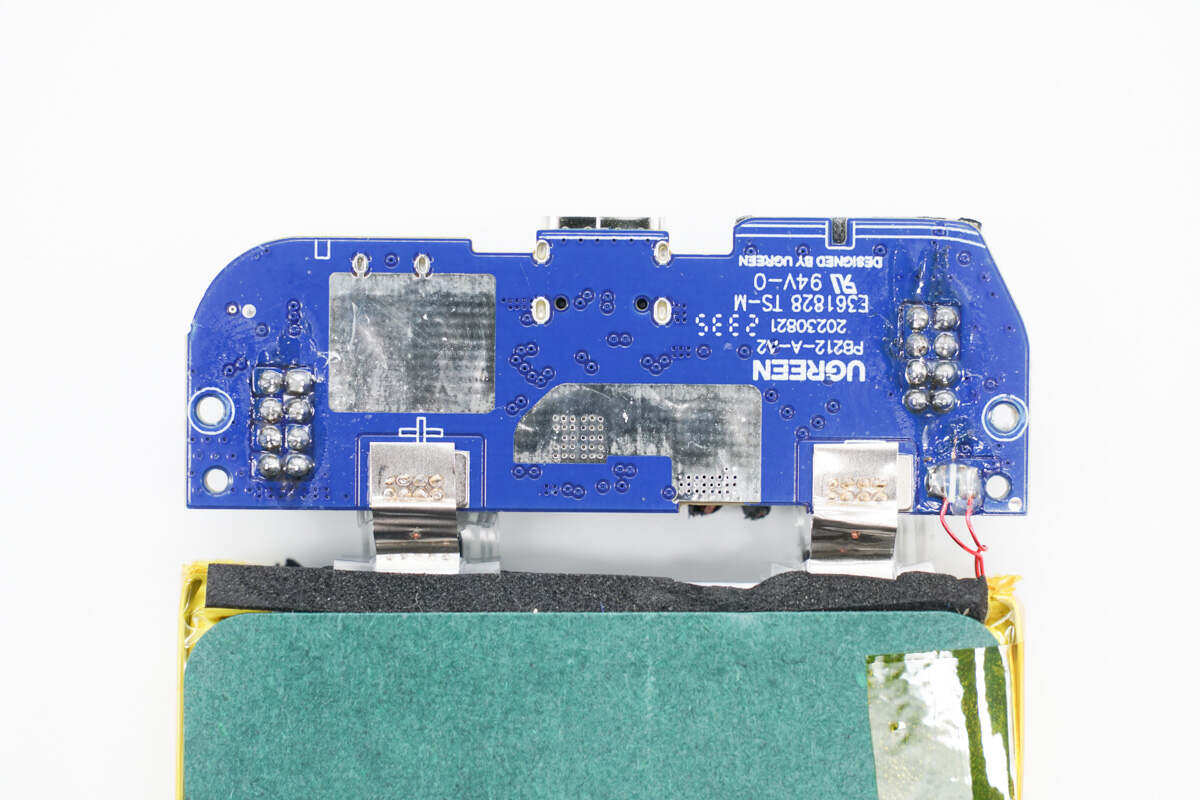

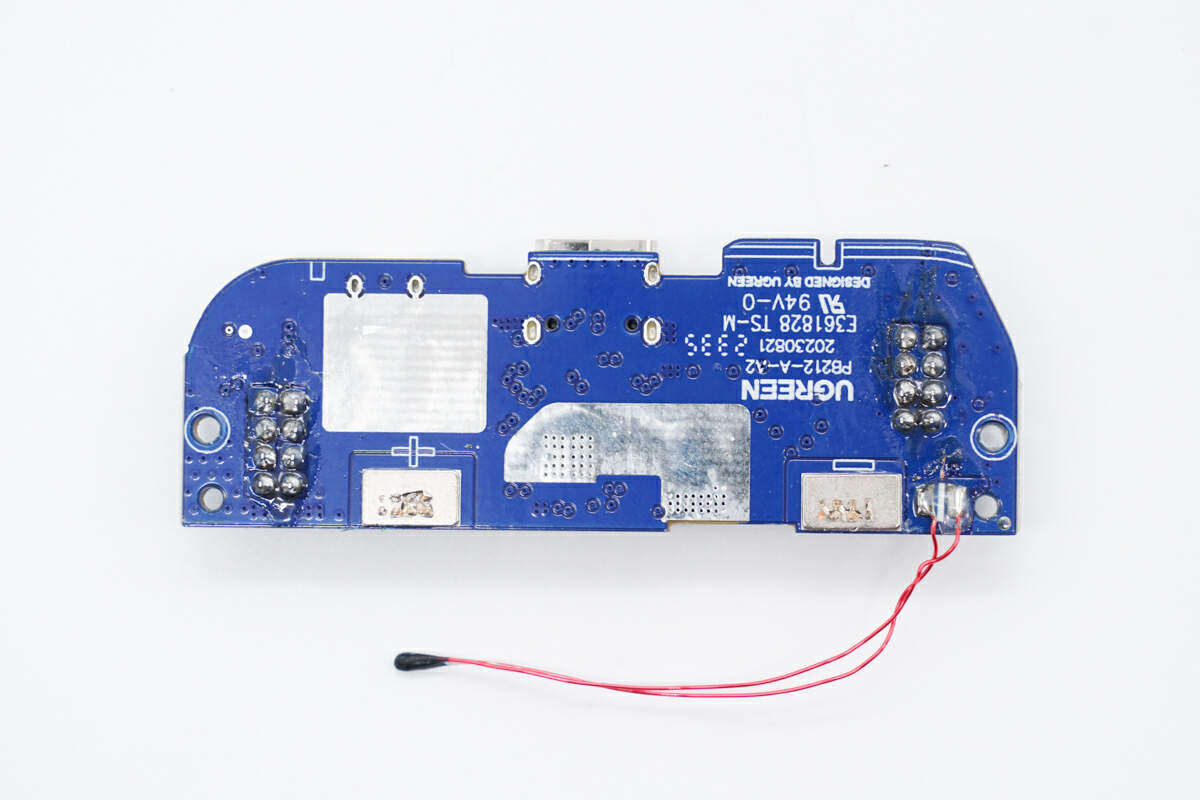

The positive and negative terminals of the battery are connected to the PCBA module through spot welding, and the thermistor is welded to the lower right corner of the PCBA module.

The other side is connected to another PCB through pin headers.

There is also tape on the battery for insulation.

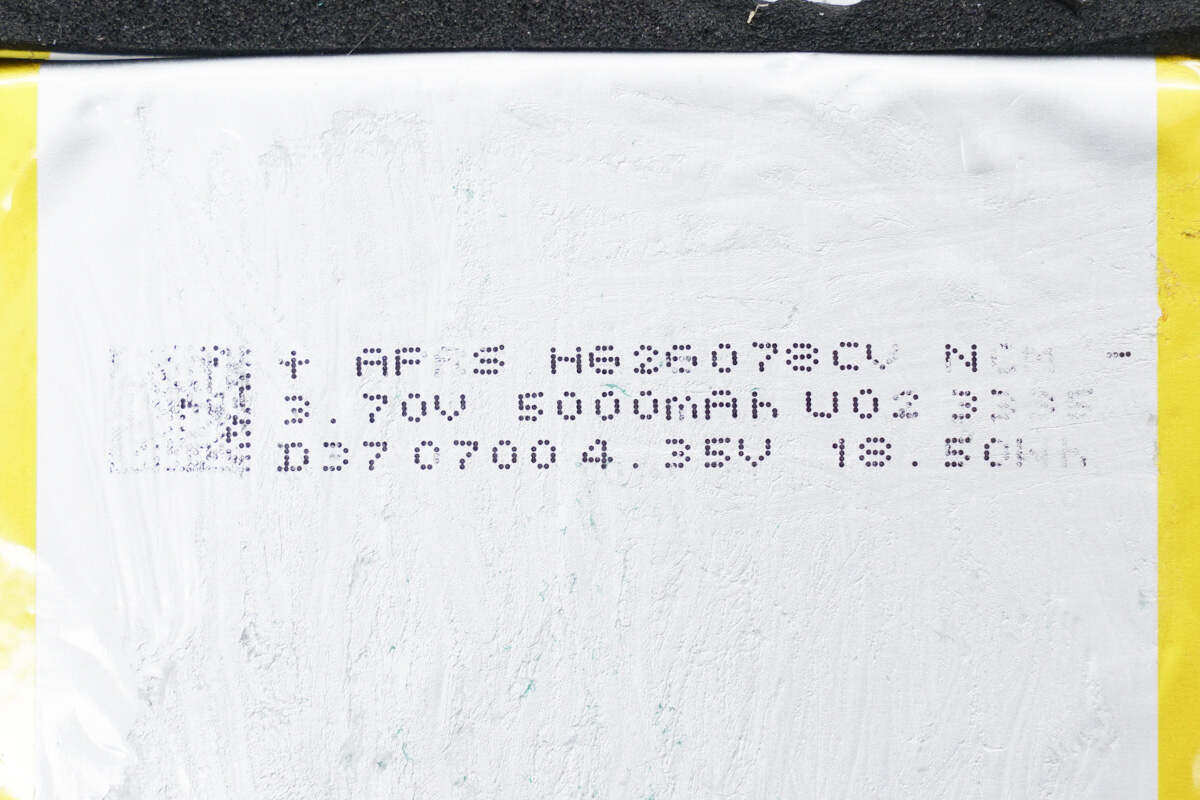

The built-in battery of the mobile power supply is from Ampreis. The size is 626078, the thickness is 6.2mm, the width is 60mm, and the length is 78mm. The battery has a rated voltage of 3.7V and a capacity of 5000mAh. Two pieces are connected in parallel to form a capacity of 10000mAh.

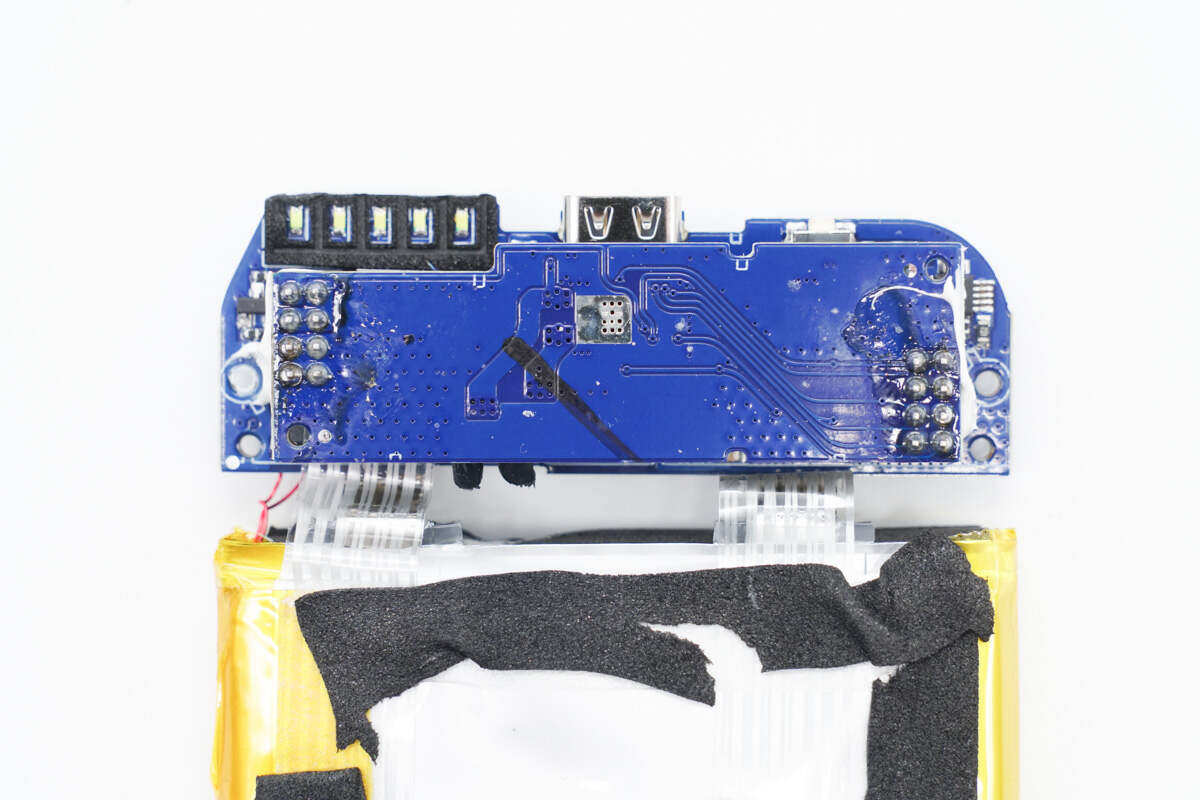

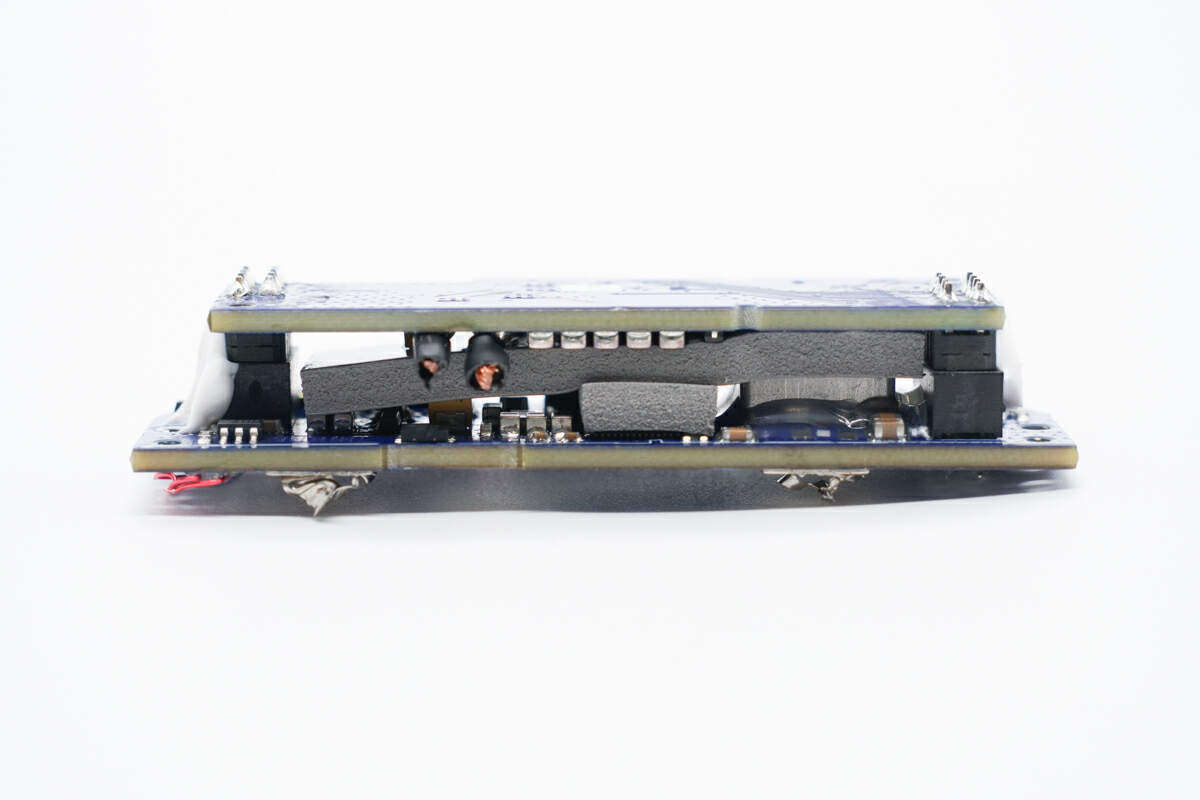

There is a thermal pad between the two PCBs for heat dissipation.

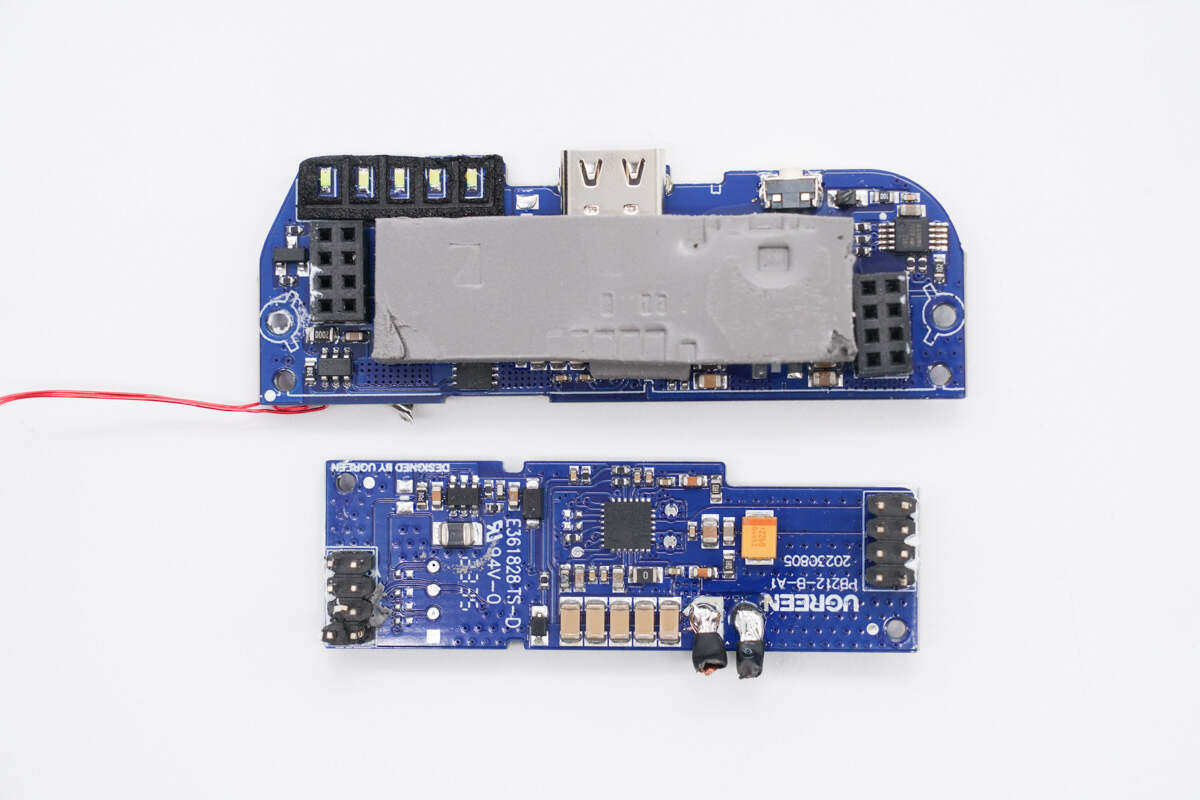

Separate the two PCBs connected by pin headers.

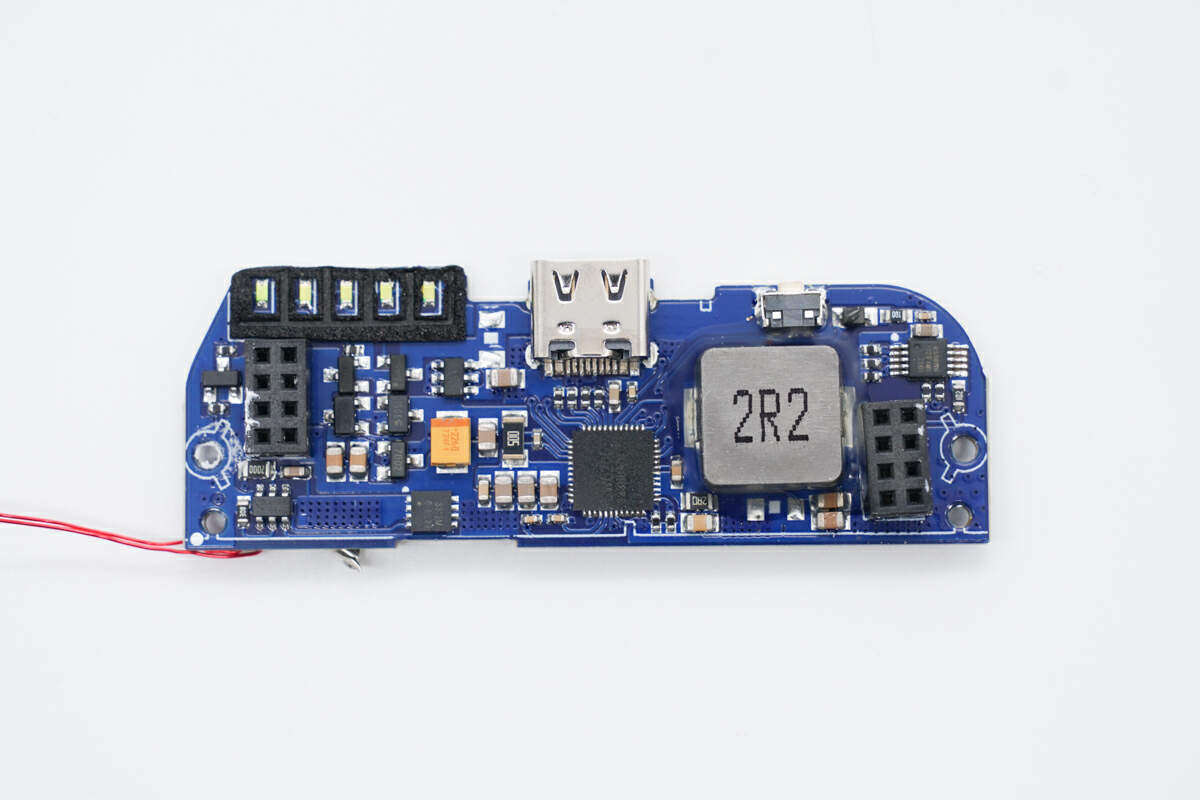

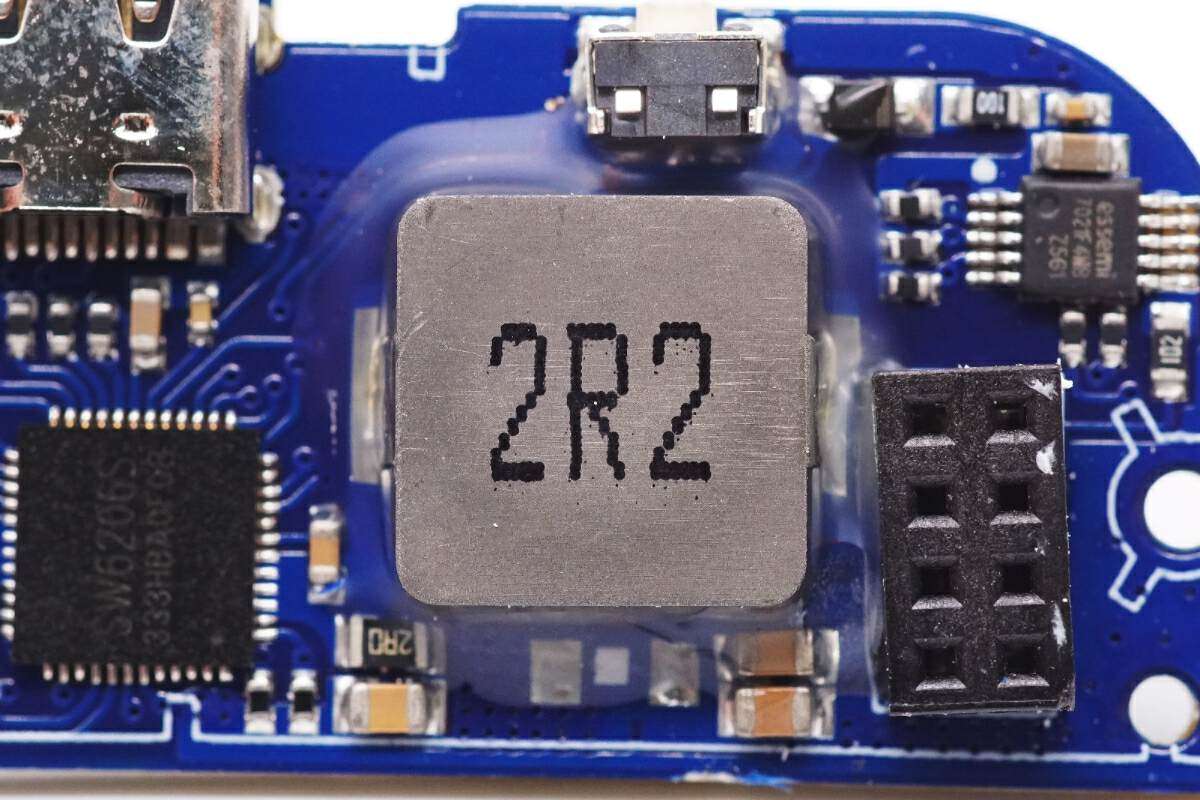

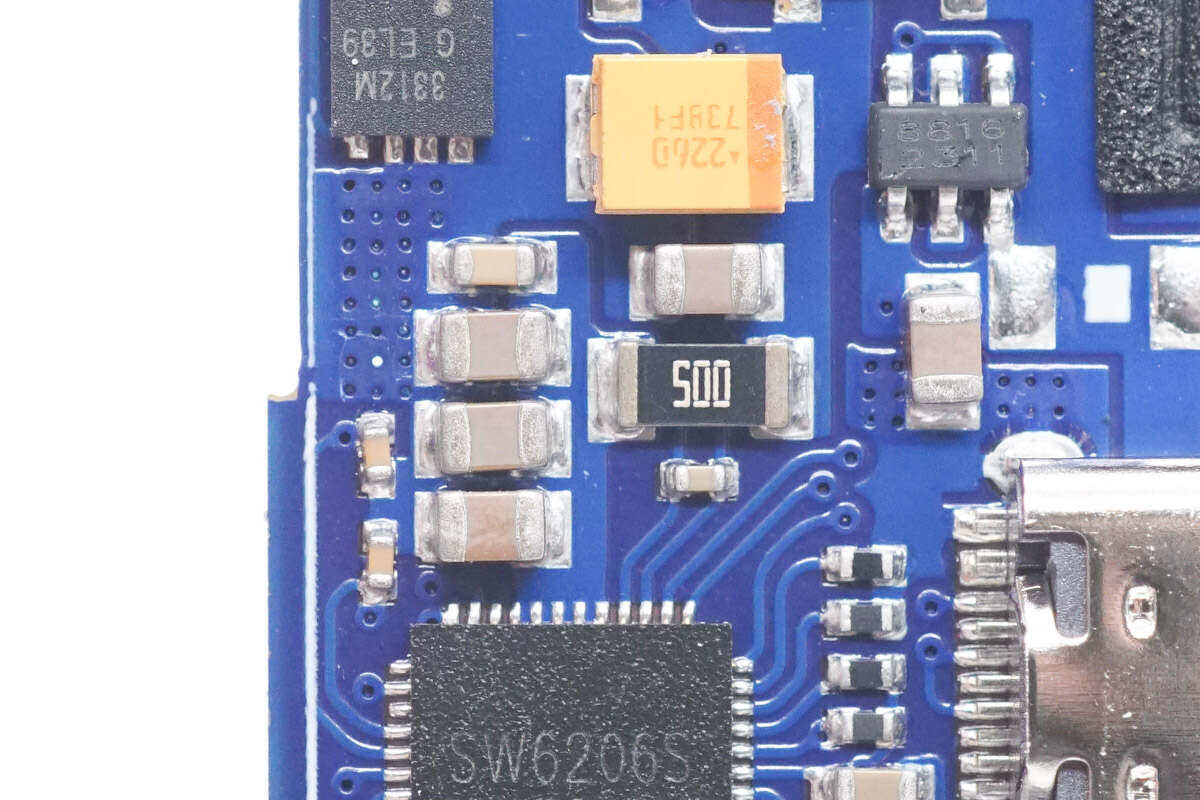

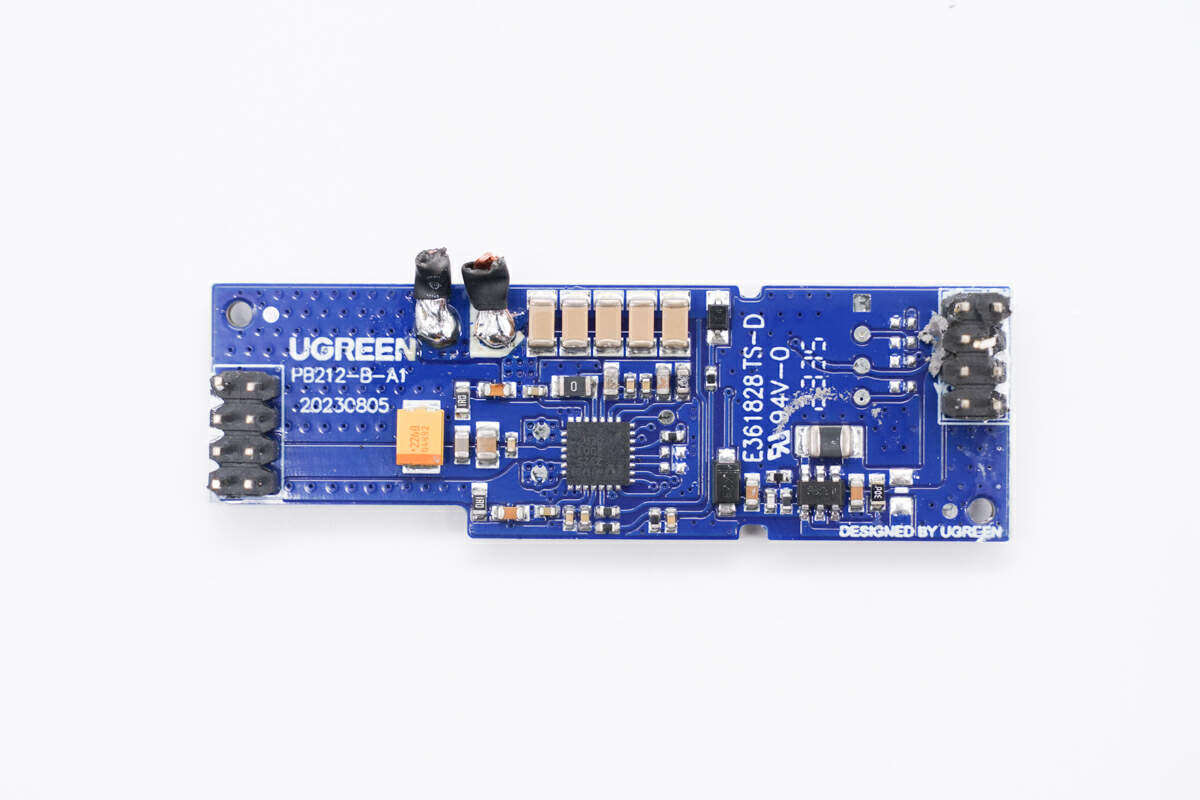

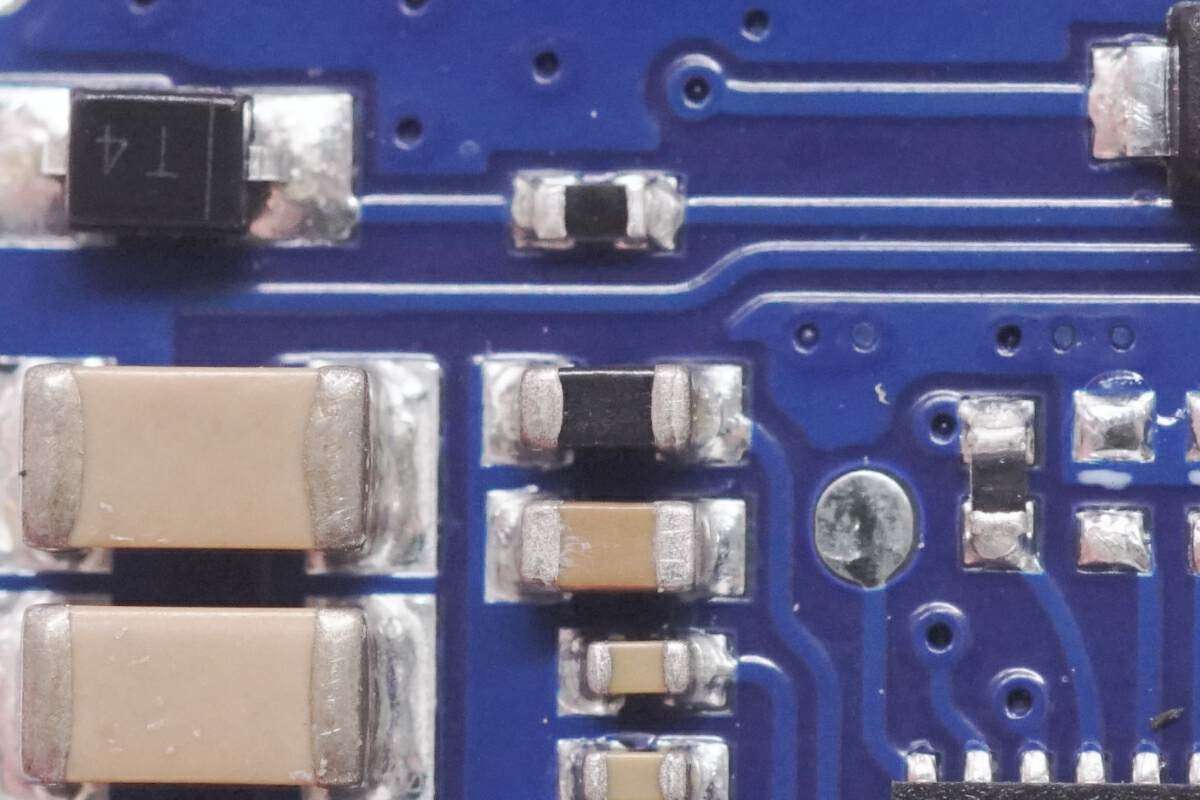

One of the larger PCBs is a mobile power supply board, welding power indicator light, USB-C interface, power detection button, battery protection chip, battery protection tube, mobile power supply main control chip and alloy inductor. On both sides, the other PCB is connected PCB connector.

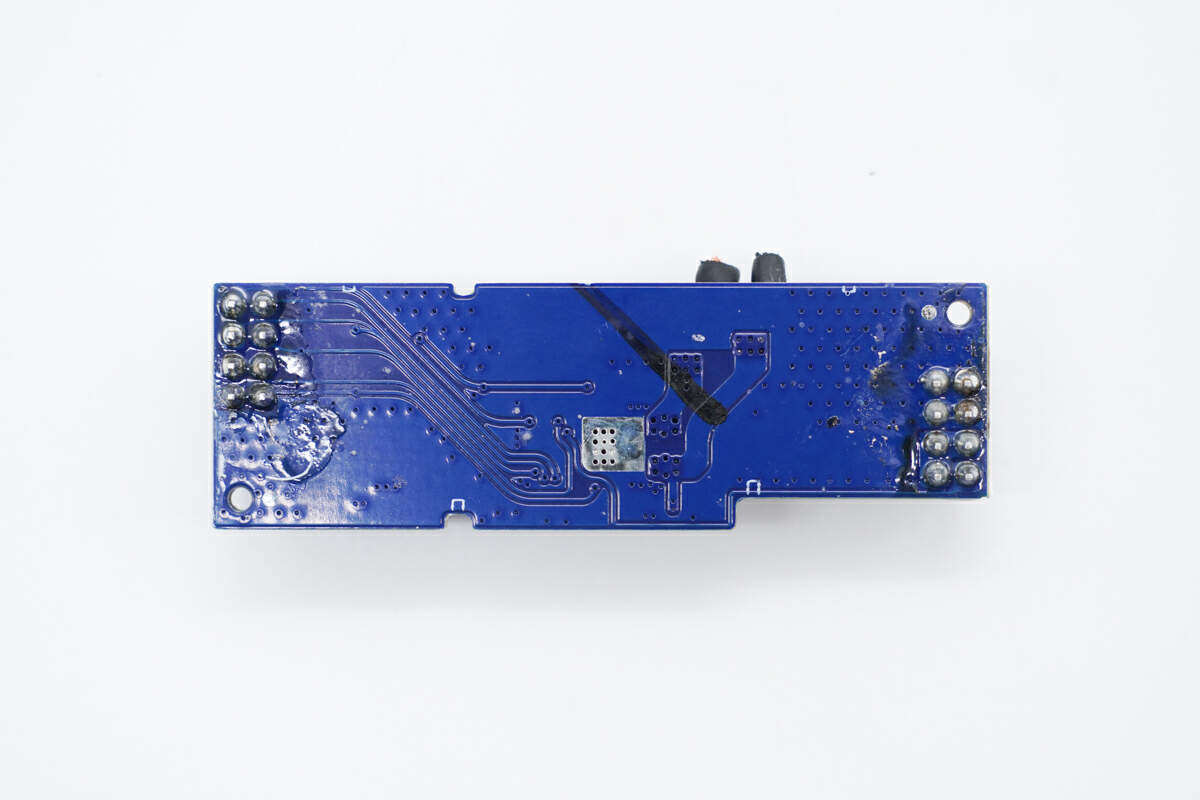

Weld the battery and NTC thermistor on the back of the PCBA module.

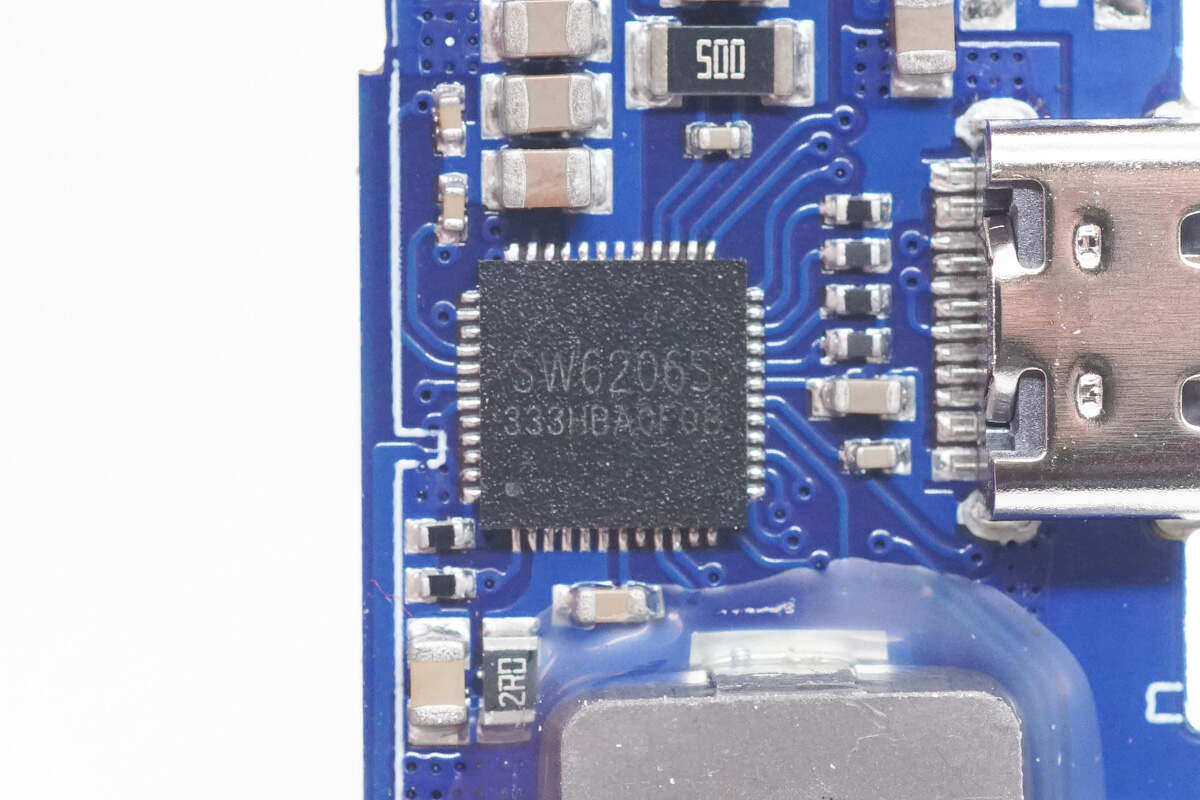

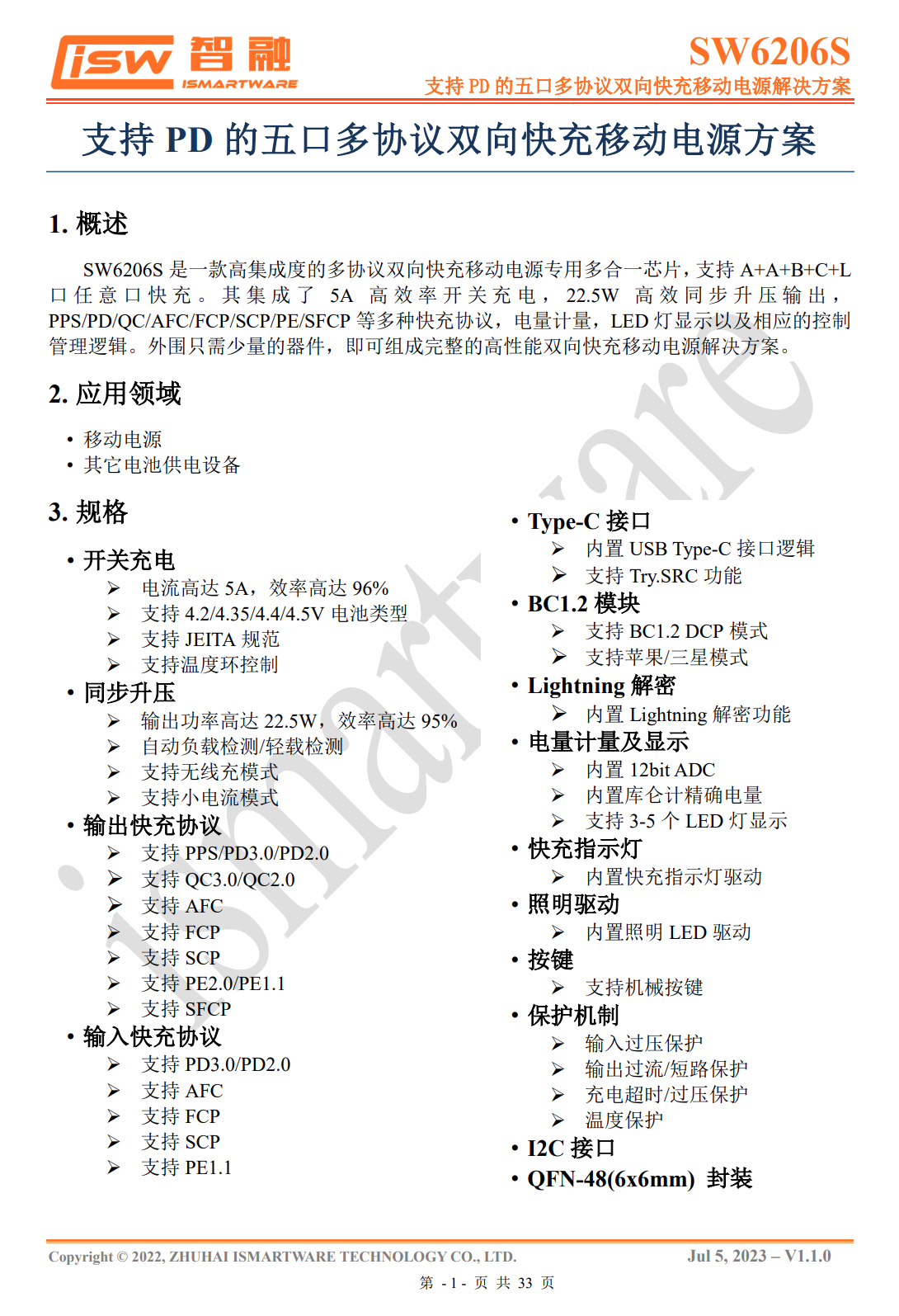

The main control chip of the mobile power supply adopts Zhirong SW6206S. This is a highly integrated multi-protocol two-way fast charging mobile power supply dedicated all-in-one chip that supports fast charging of any A+A+B+C+L port. The chip integrates 5A high-efficiency switch charging, 22.5W high-efficiency synchronous boost output, supports PPS, USB PD, QC, AFC, FCP, SCP, PE, SFCP and other fast charging protocols, power measurement, LED lights, digital tube display and corresponding control management logic. Only a small number of peripheral components are needed to form a complete high-performance two-way fast charging mobile power solution.

Charging Head Network learned that products using the Zhilong SW6206 main control chip include Momis 10000mAh wireless charging power bank , iWALK 10000mAh racing treasure power bank , Mohu 10000mAh color screen wireless fast charging power bank , and Maiduoduo 10000mAh magnetic wireless charging power bank. Power bank , NetEase Intelligent Manufacturing 10000mAh wireless charging power bank , Pinsheng 20000mAh 22.5W full protocol fast charging power bank , Romans 10000mAh 22.5W super fast charging power bank , etc.

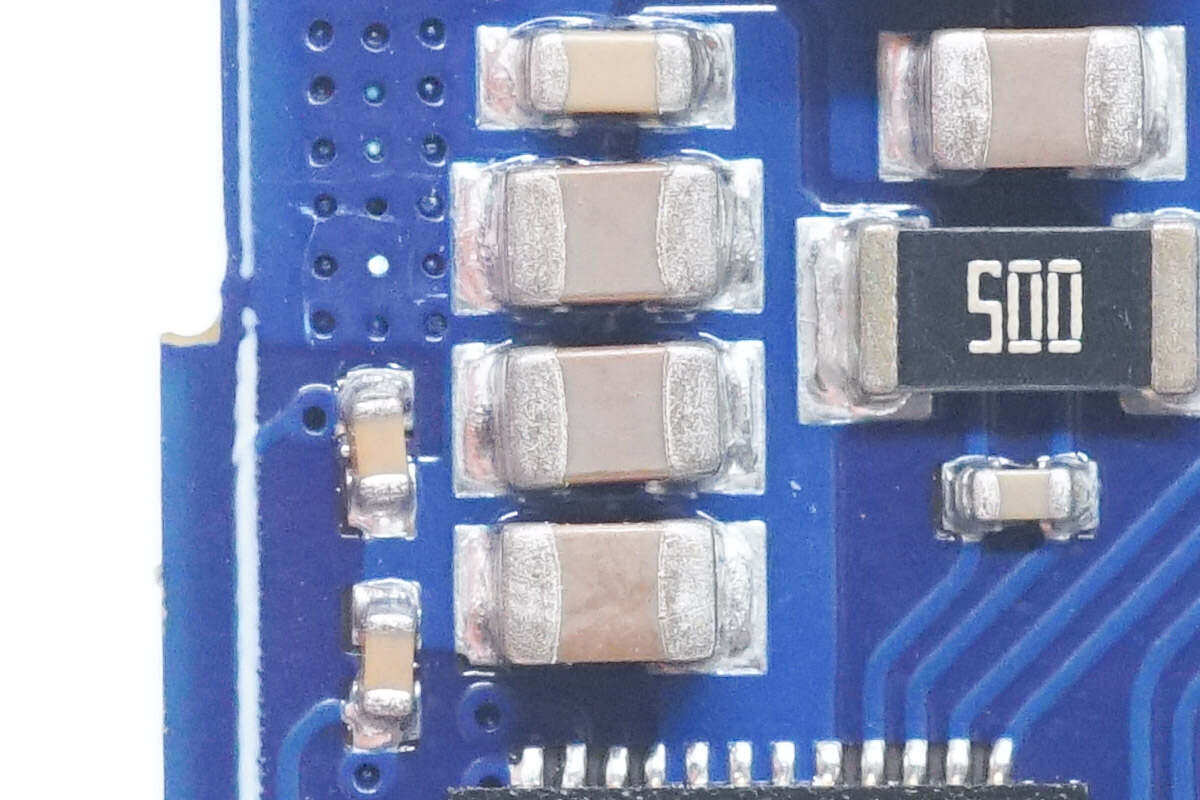

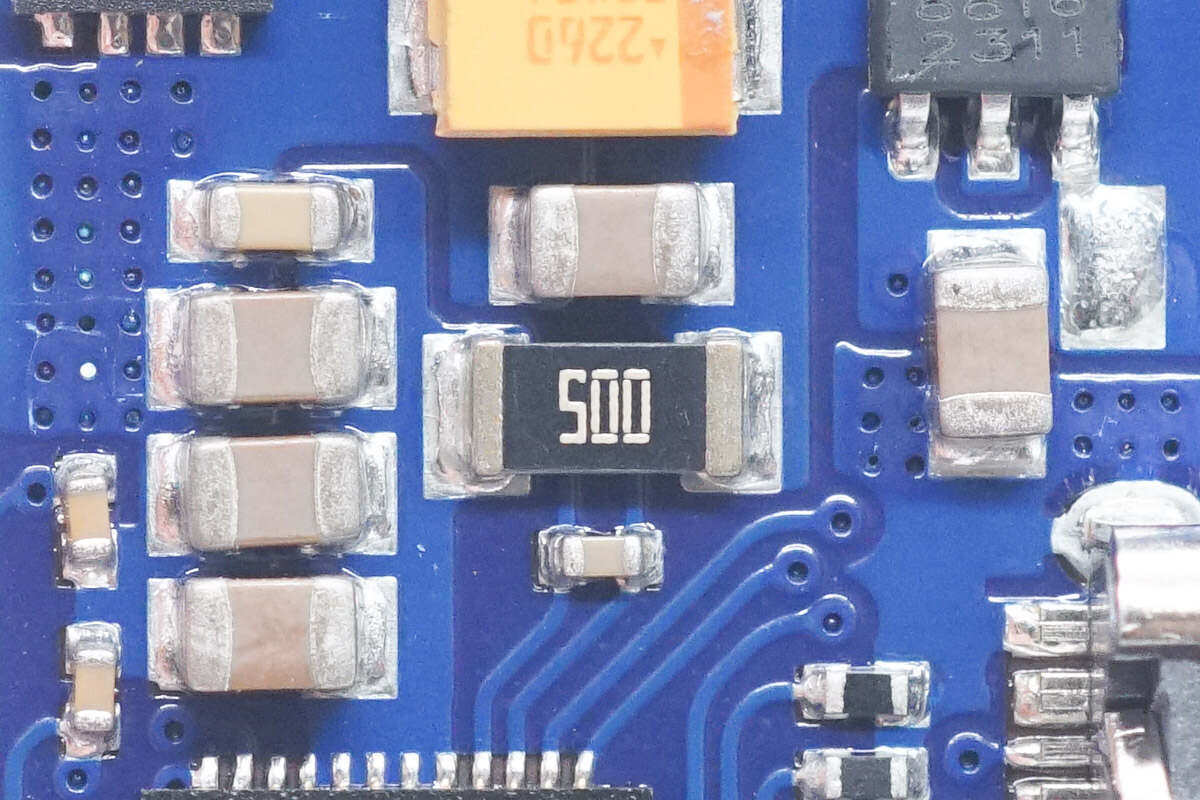

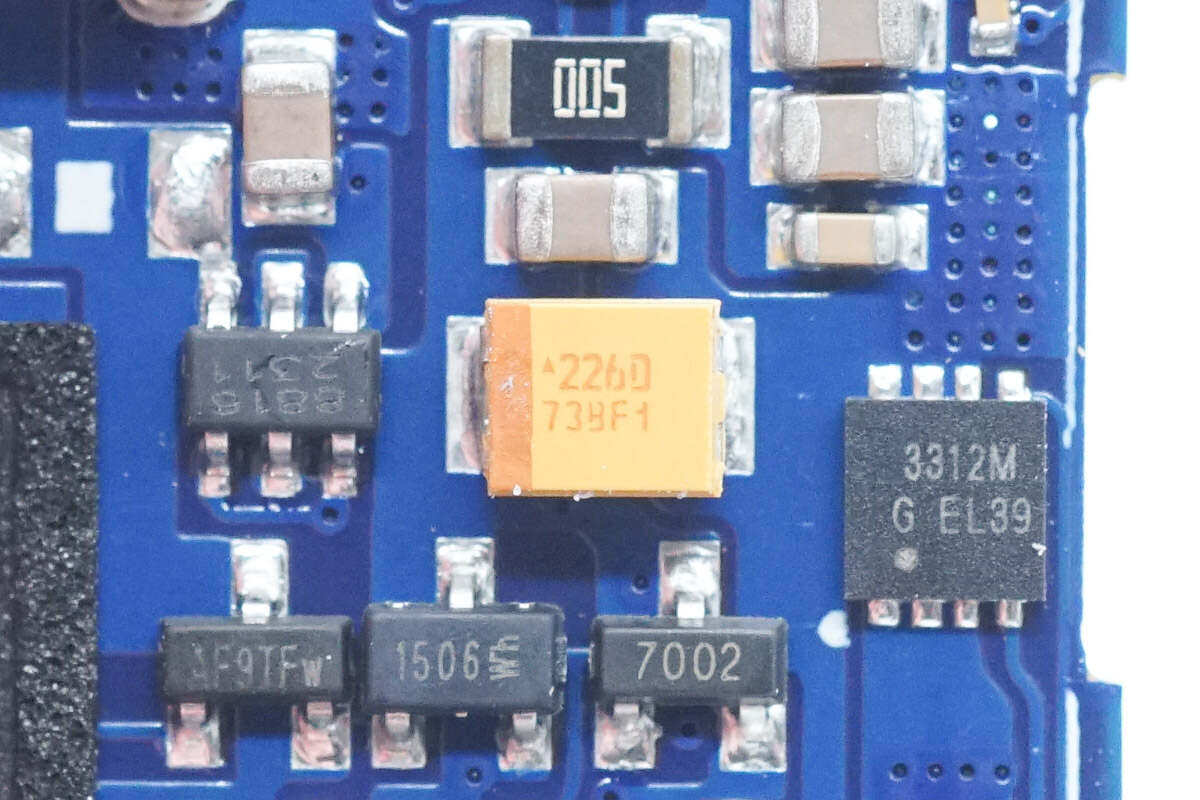

2.2μH alloy inductor is glued and reinforced.

Close-up of the output filter capacitor and current-sense resistor.

4 MLCC capacitors are used for output filtering.

A 5mΩ resistor is used for output current sensing.

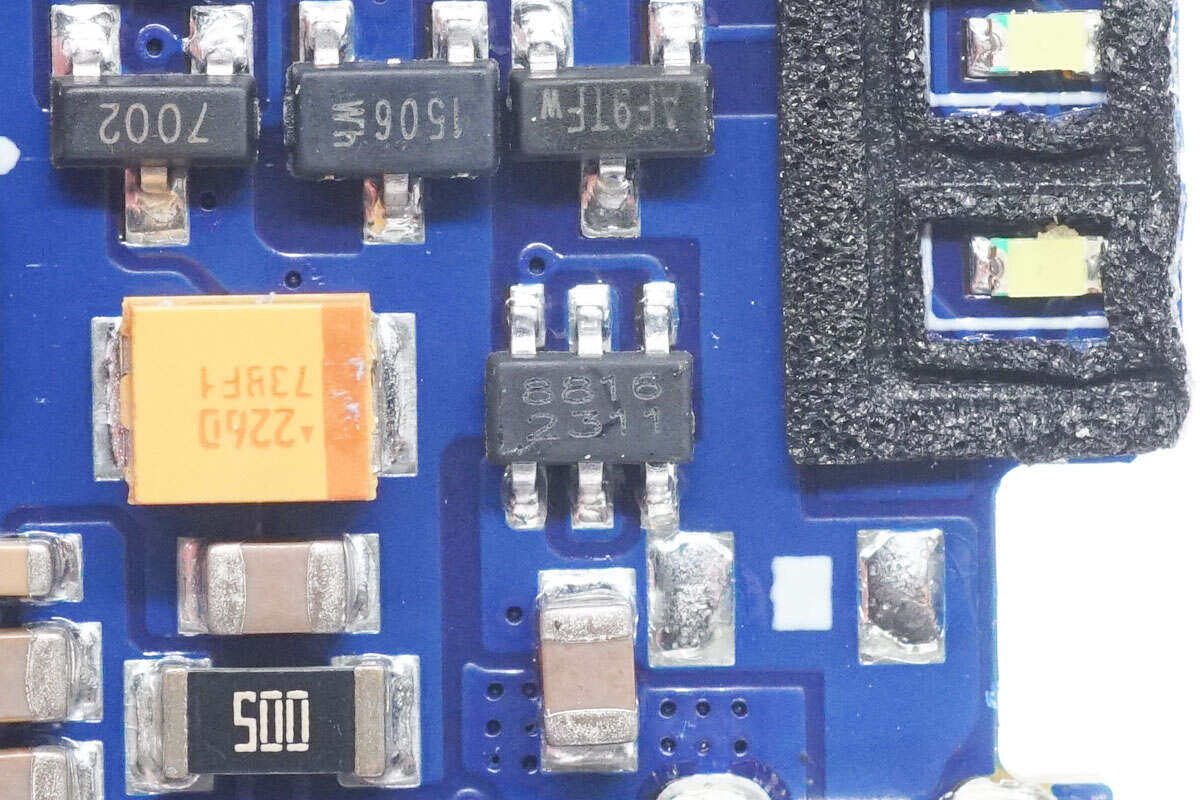

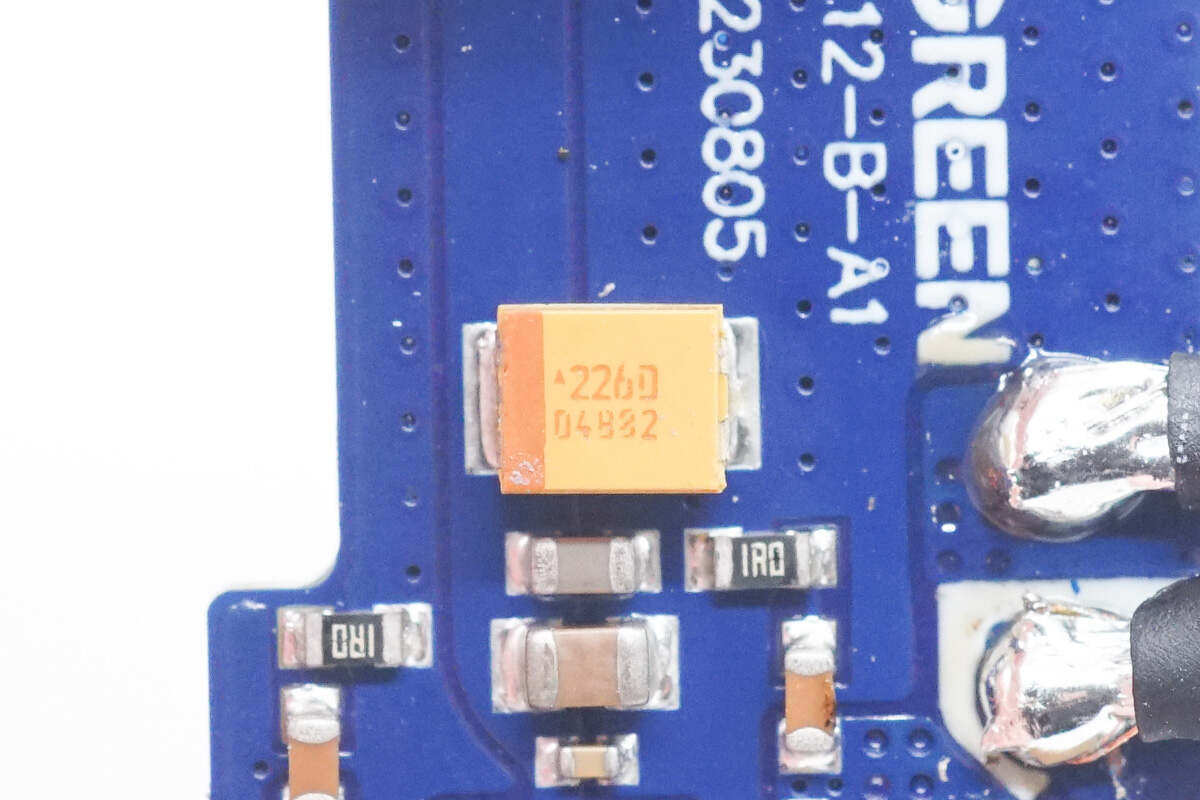

The filter tantalum capacitor is from Kyocera AVX and has a specification of 22μF 20V.

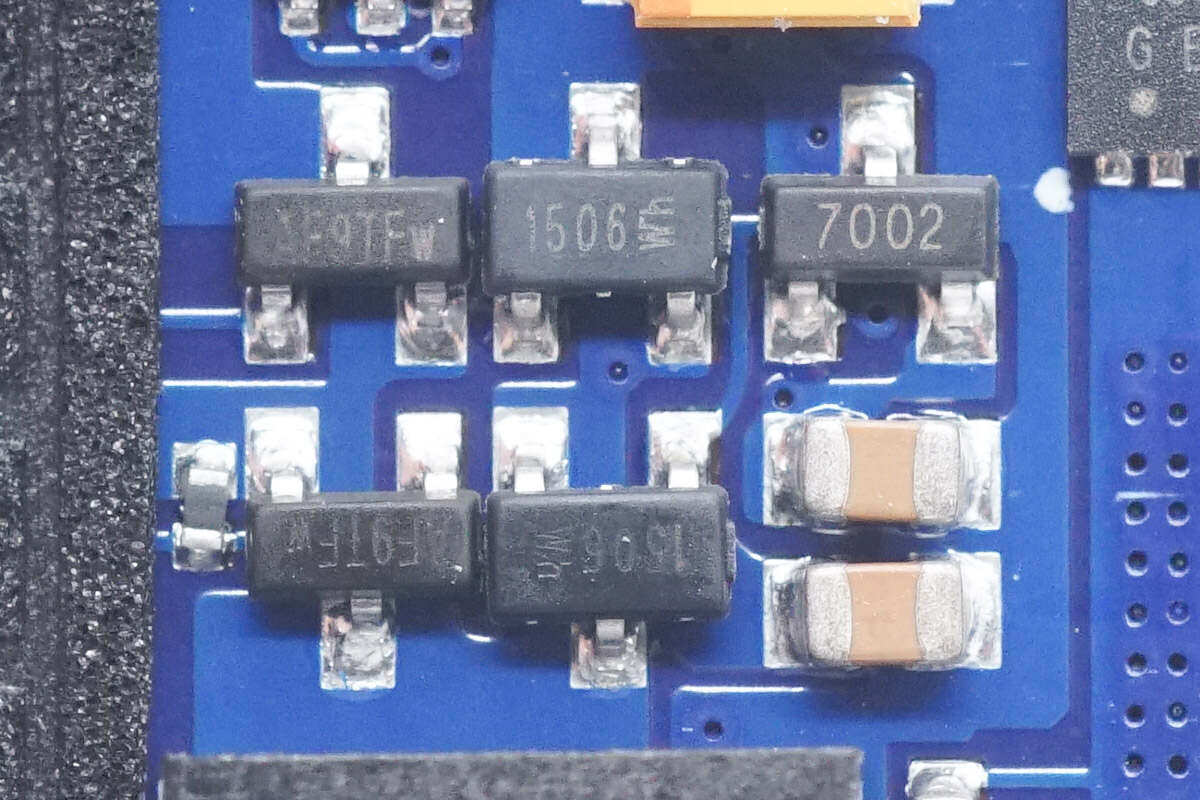

VBUS switch tube is used for interface switching.

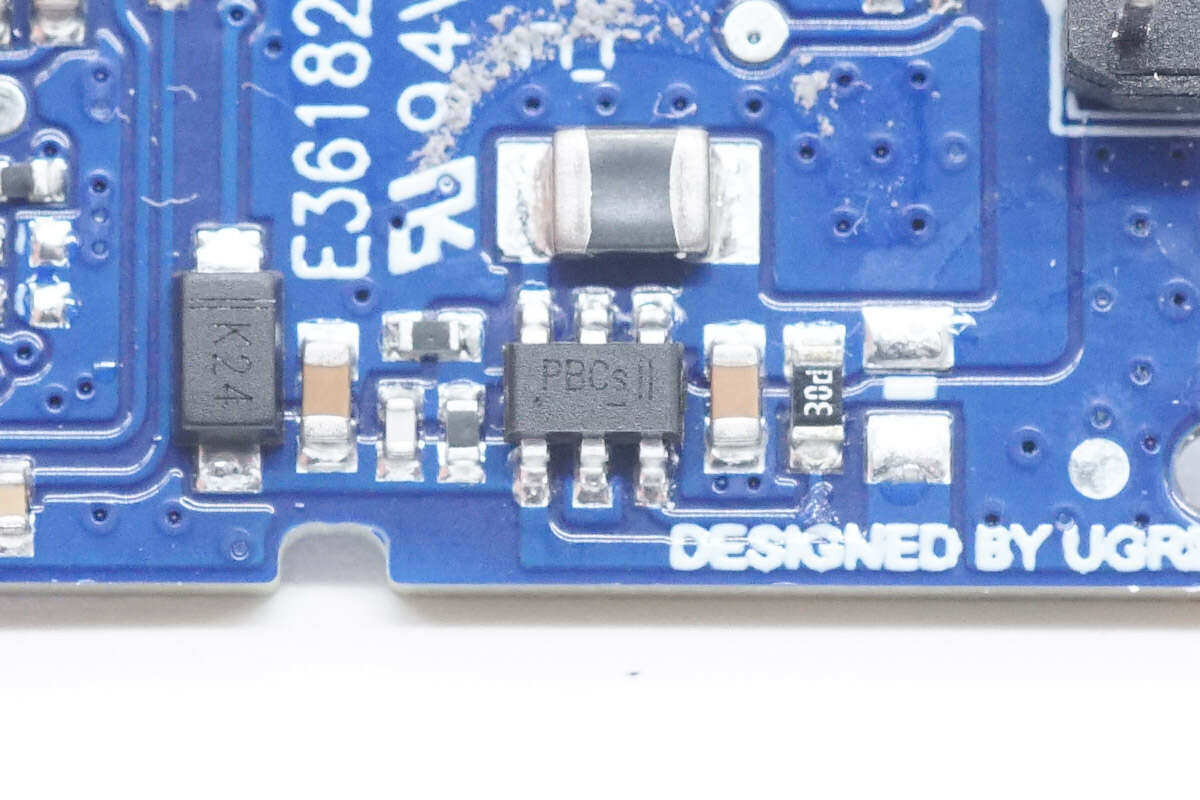

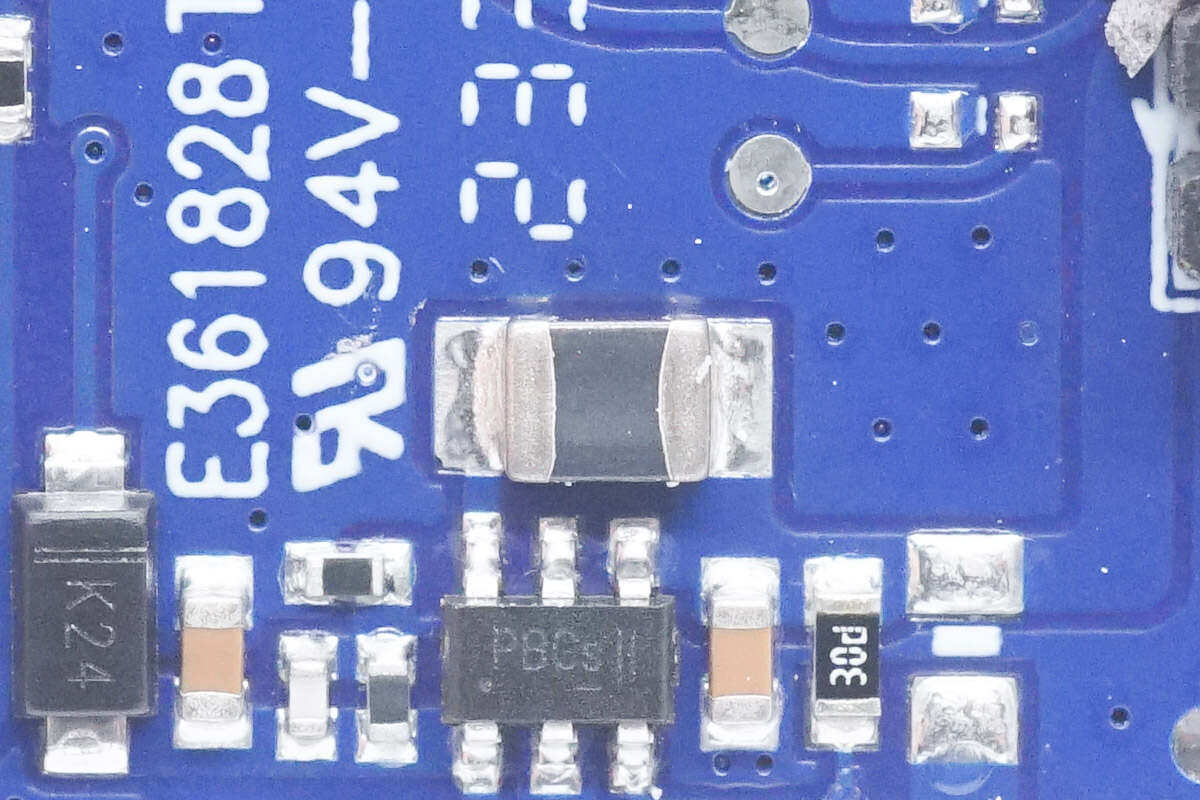

A dual MOS tube comes from Core Cell, model PE8816, withstand voltage 16V, conductance resistance 5.5mΩ, and is packaged in SOT23-6.

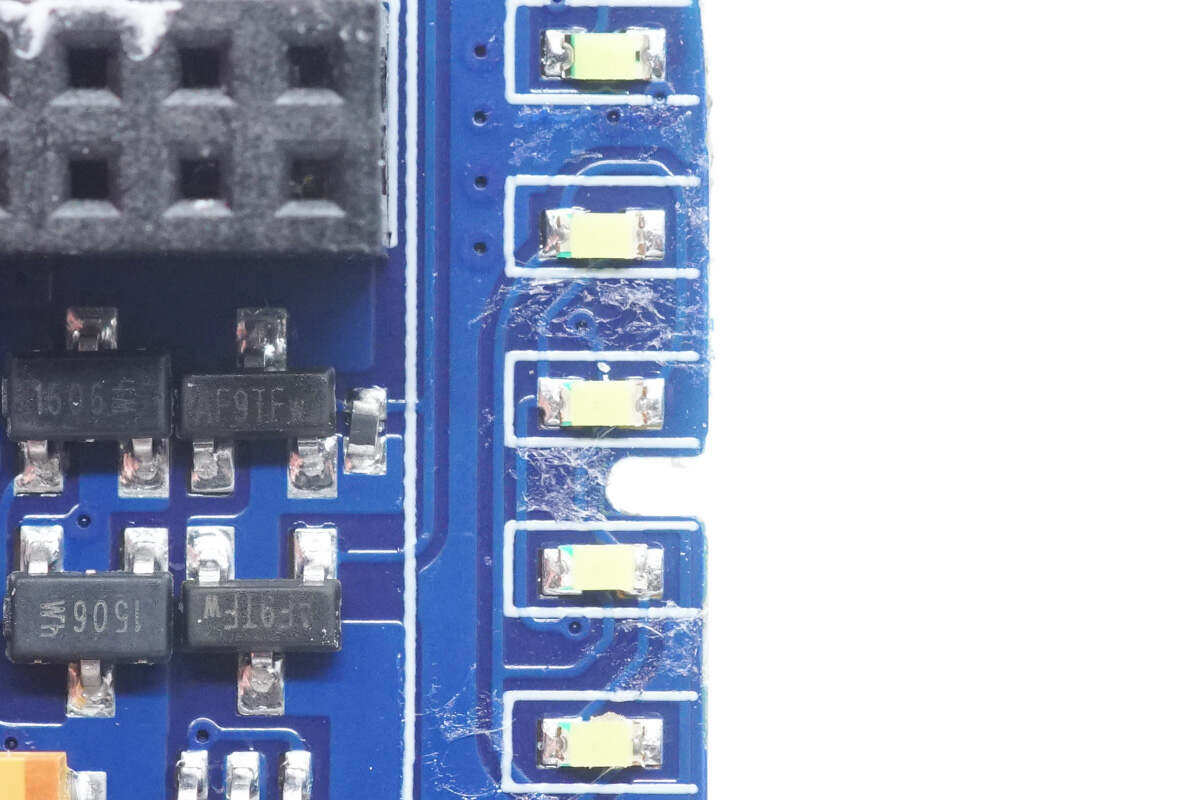

Five SMD LEDs are used for power indicator lights.

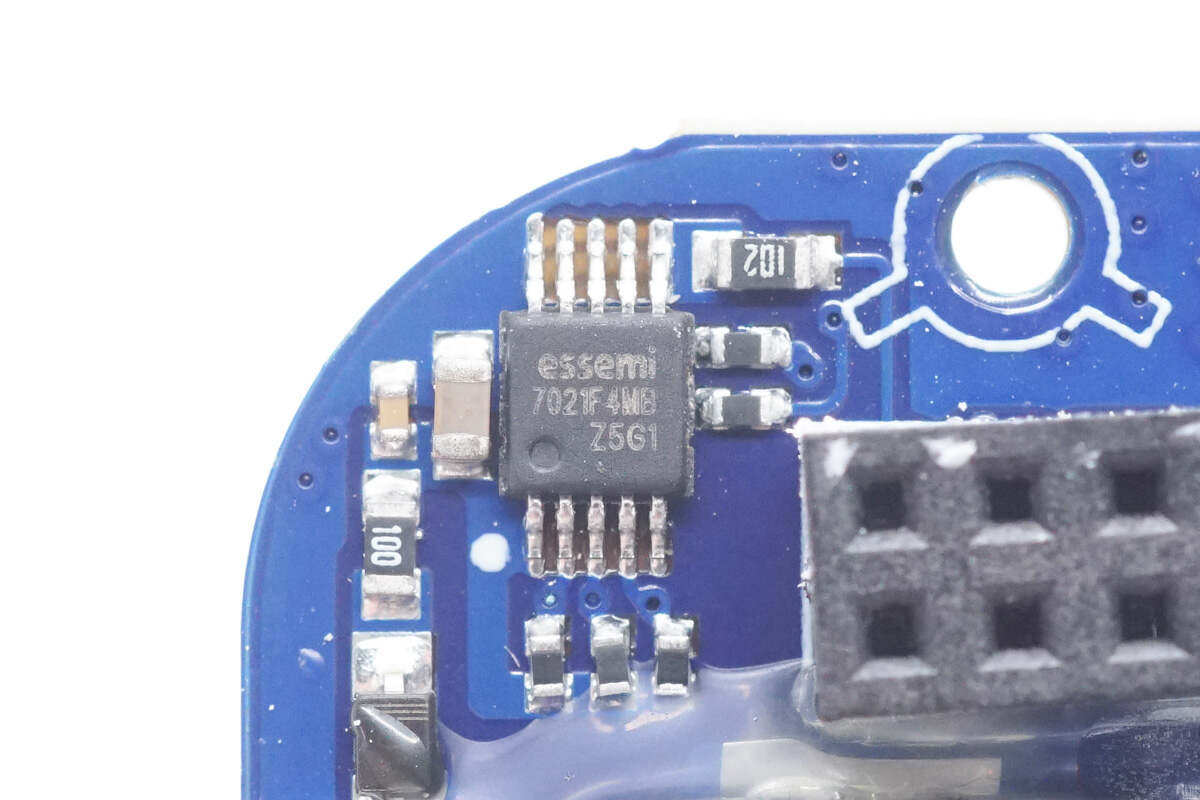

An MCU comes from Neusoft Carrier, model ES7P7021F4MB, which is a RISC core with integrated FLASH memory and 128-byte SRAM, and is packaged in MSOP10.

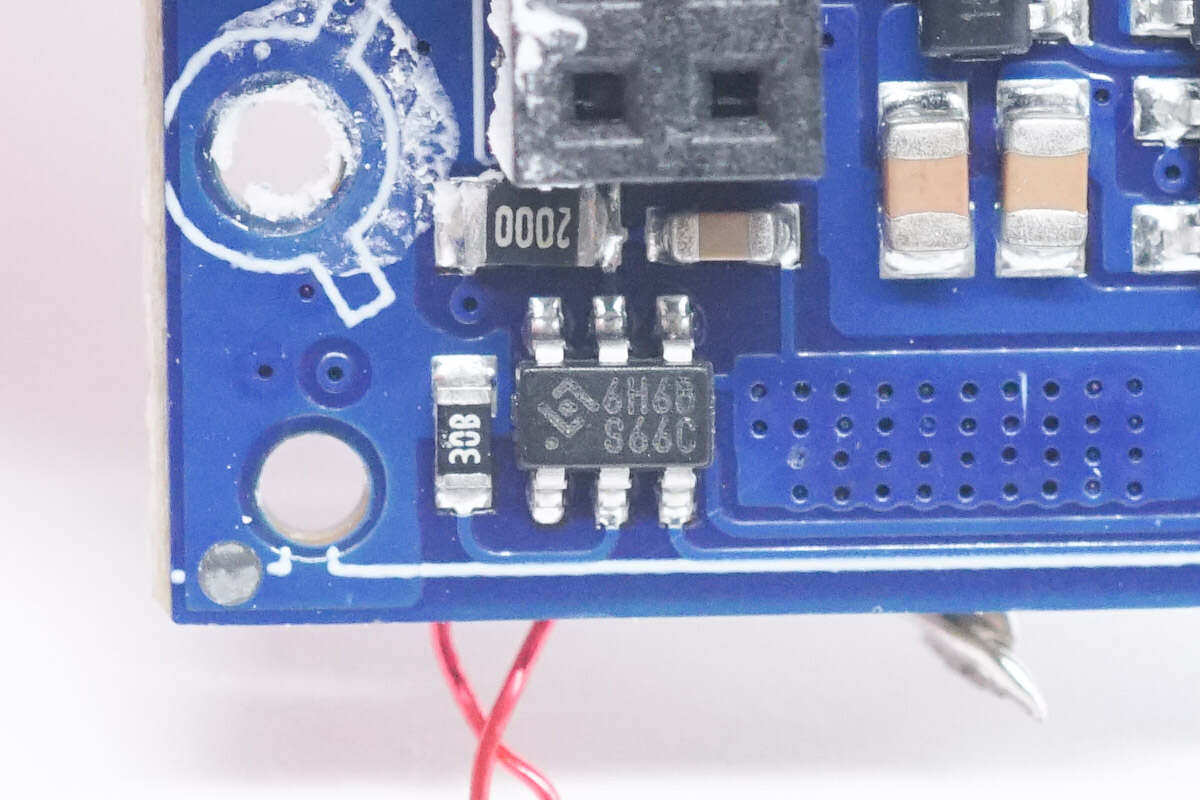

The battery protection chip is from Hongkang, and the screen printing is 6H6B.

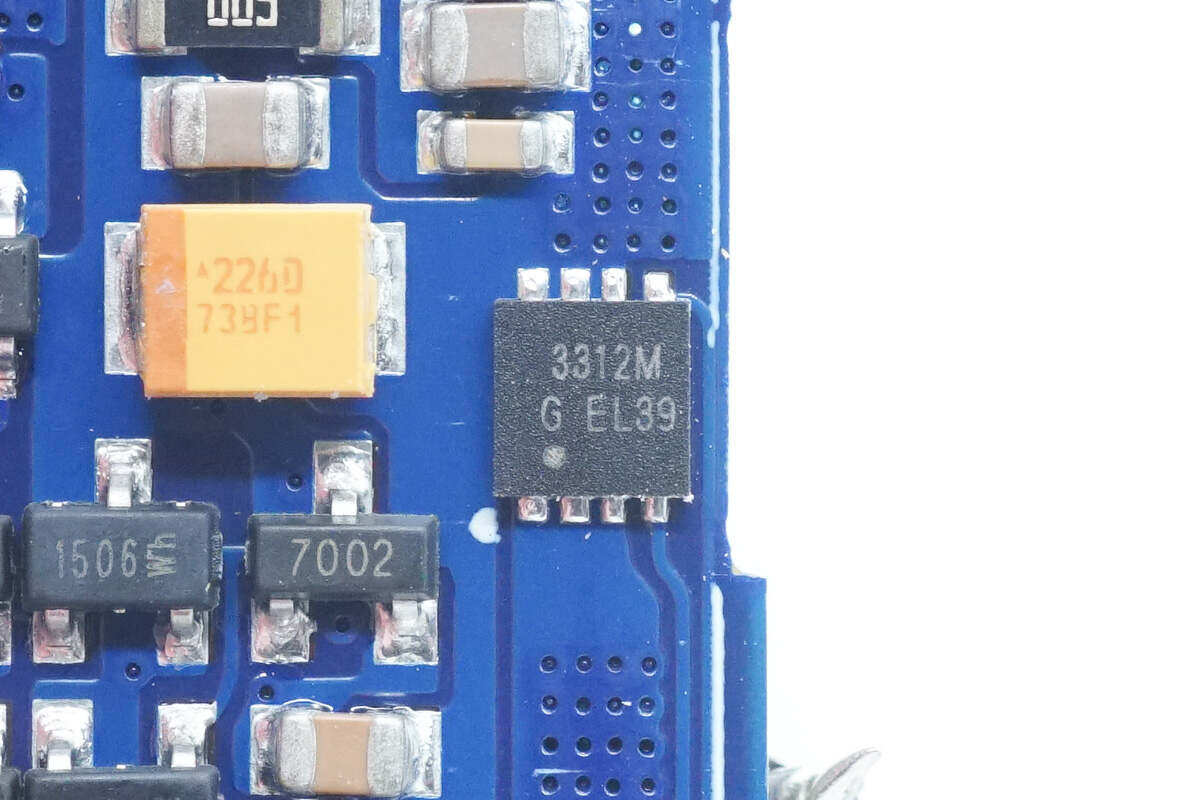

The battery protection tube is from Core Power, model PED3312M. It is a dual NMOS with a voltage resistance of 18V and a conduction resistance of 3.4mΩ. It is used for battery output control.

Close-up of a thermistor that detects battery temperature.

Overview of the wireless charging PCBA module, front welding filter capacitor, wireless charging main control, boost main control chip and resonant capacitor.

There are no welding components on the back of the PCBA module, and the position corresponding to the wireless charging main control is exposed with copper and tin to enhance heat dissipation performance.

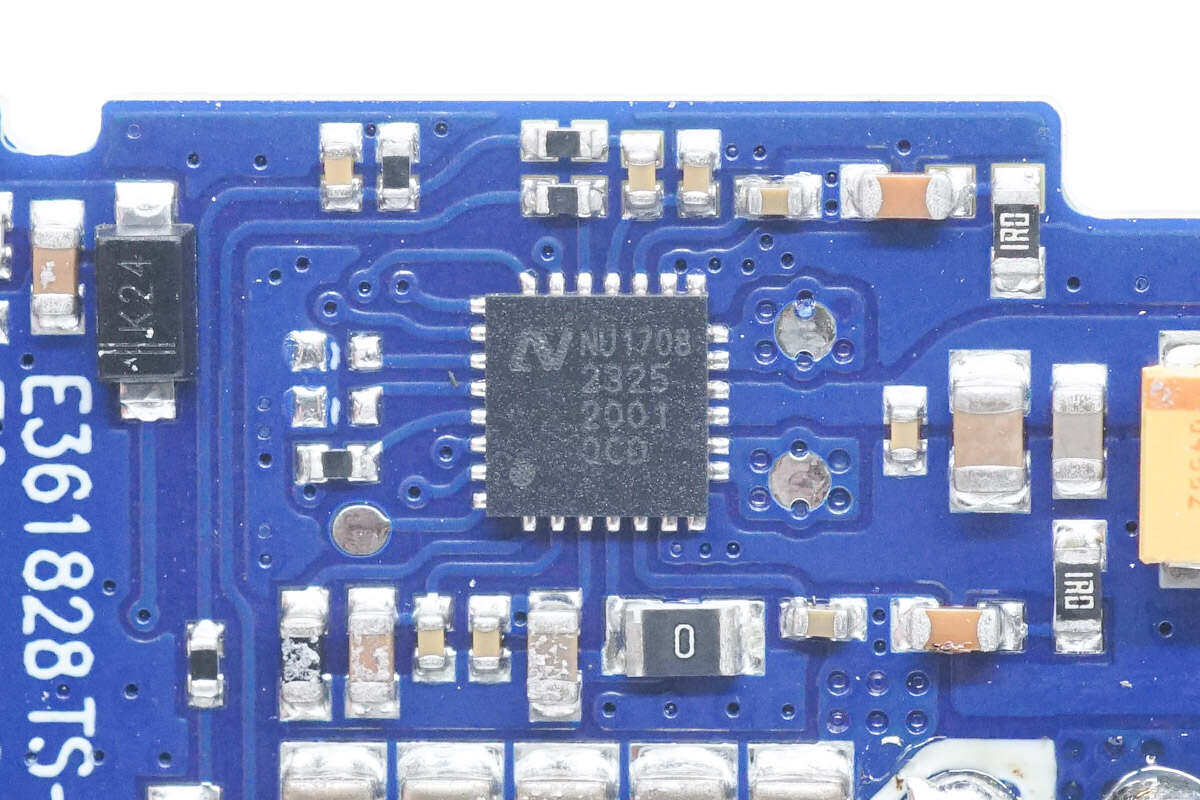

The wireless charging main control chip adopts Voda NU1708, which is a highly integrated wireless charging transmitter chip. It integrates MCU and wireless charging power level internally. It integrates the traditional wireless charging main control chip and power full-bridge chip in one package, which greatly improves the efficiency of wireless charging. Save space.

NU1708 has built-in high-precision non-destructive current detection for foreign object detection and in-band communication. The IC integrates input voltage under-voltage lockout, over-voltage protection, over-current protection and thermal shutdown protection functions, further enhancing the overall system solution. reliability.

NU1708 supports I2C and UART interfaces, and has a built-in ADC for collecting charging parameter information. It supports QC and PD fast charging and power extraction functions, has low quiescent current, and a single chip can realize a complete wireless charging design with an output power of up to 30W.

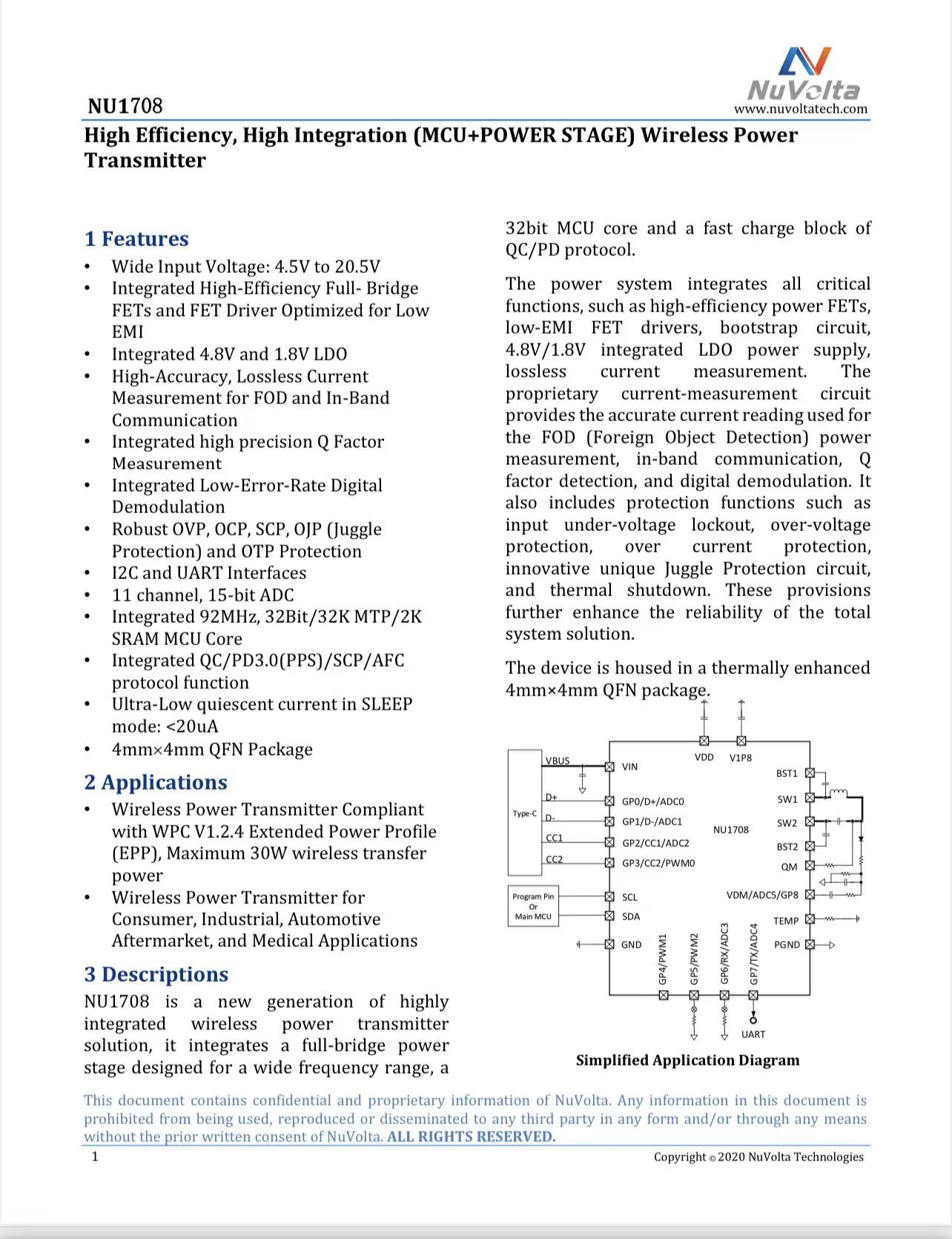

Voda Semiconductor NU1708 details.

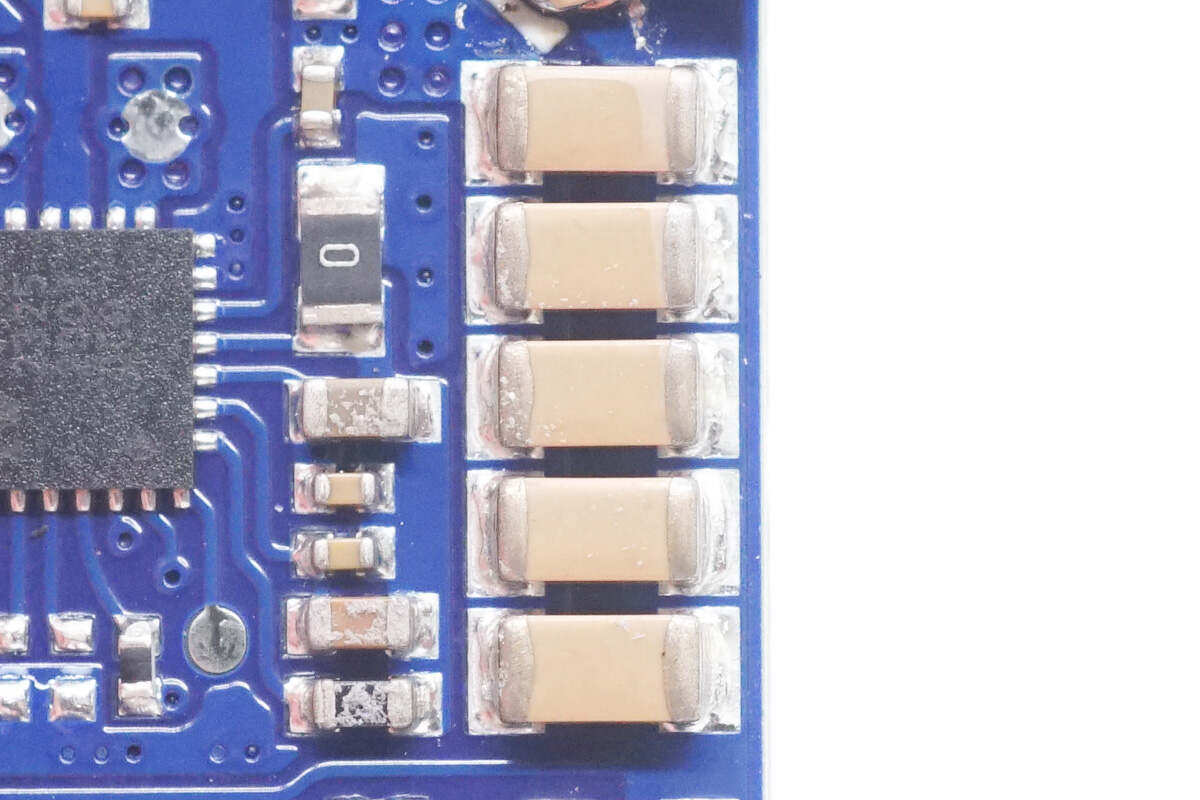

Close-up of five NPO resonant capacitors connected in parallel.

An NTC thermistor is welded on the edge of the wireless charging main control chip to detect the temperature of the PCBA module.

Close-up of tantalum capacitors used for power supply filtering.

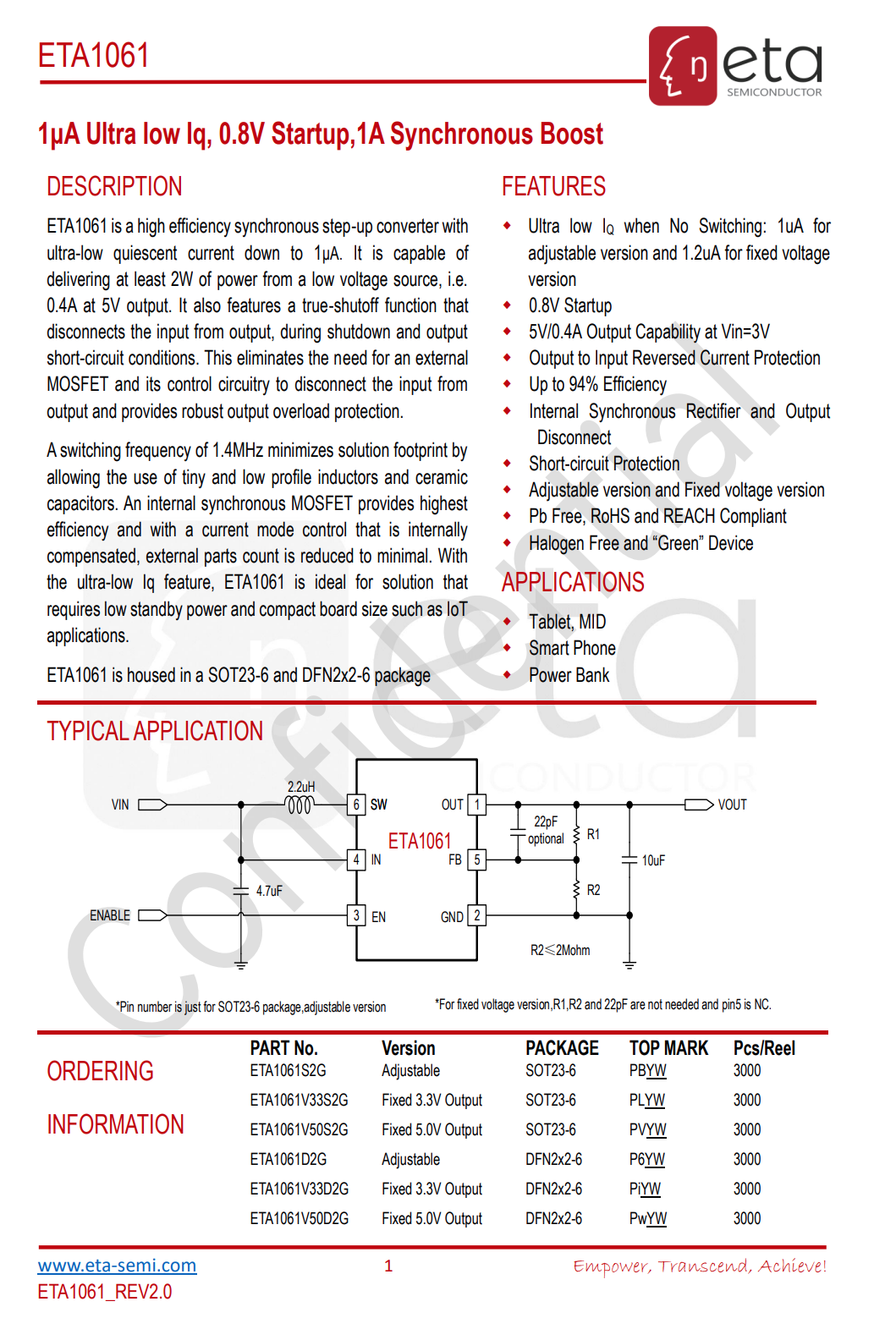

A boost chip comes from Etai Semiconductor, model ETA1061. It is a synchronous boost converter with 1μA ultra-low standby current, 0.8V startup voltage, and 1A output current. The operating frequency is 1.4MHz and has an output true shutdown function. The chip has built-in short circuit protection and is available in adjustable voltage and fixed output voltage models. ETA1061 is available in DFN and SOT23 packages to meet the needs of different occasions.

Yutai Semiconductor ETA1061 data information.

Close-up of the boost inductor used.

Take a look at all the disassembly and take a family photo.

Summary of disassembly of charging head network

This magnetic wireless power bank from Lulian has a built-in 10000mAh battery and supports 15W wireless charging and 20W wired charging. Wireless charging is easy to use and wired charging is faster. This magnetic power bank also supports low-current mode, so you don’t have to worry about automatic shutdown when charging your headphones. In addition, it also supports wireless charging output while charging, which is very comprehensive.

Charging Head Network learned through disassembly that the Greenlink magnetic wireless charging power bank has a built-in Ampreis lithium battery, and two 5000mAh batteries are connected in parallel to form a 10000mAh capacity. It uses Zhirong SW6206S mobile power supply main control chip and Voda NU1708 wireless charging main control chip, and also uses Yutai ETA1061 for voltage boosting. Thermal pads are used between the mobile power supply PCBs to enhance heat dissipation. Both the battery and PCBA modules are equipped with thermistors for temperature detection. The product uses solid materials and reliable workmanship.